NEWS powered by

Andritz to upgrade flue gas treatment systems at Södra pulp mill

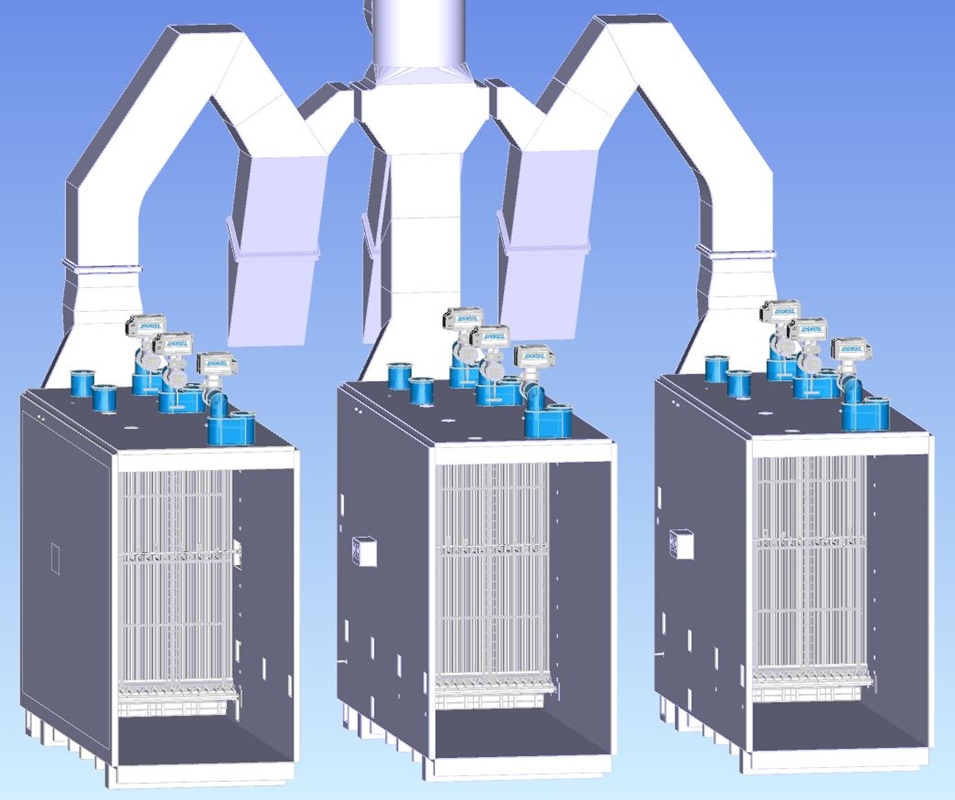

Swedish forest industry group Södra has entrusted international technology group Andritz with the upgrade of three electrostatic precipitators (ESPs) for the recovery boiler at the Mörrum pulp mill. The mechanical and electrical refurbishments will extend the ESPs’ lifetime and enable an increase of the boiler’s capacity while ensuring compliance with the current emission standards.

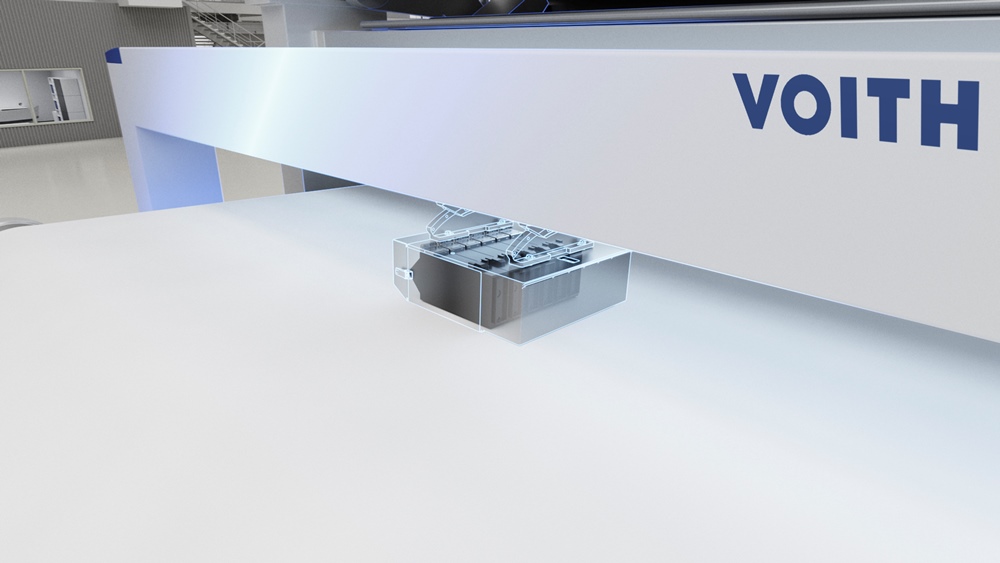

Infinity press felts – reliable high-performance fabrics for continuous use in the paper industry

The Infinity press felt family from Voith is established globally as a very good choice for heavy-duty press felts in continuous operation, in both seamed and endless versions. Since its market launch in 2011, customers worldwide have placed their trust in Infinity press felts. Infinity’s uncommon strength lies in its uniform and high-quality base fabric that ensures a laminar structure and secures the void volume over the entire operating life.

Ticket Shop open for Chemspec Europe 2024

Taking place from 19 - 20 June 2024 at the Messe Düsseldorf exhibition centre in Germany, Chemspec Europe is the meeting point to find new suppliers, enhance existing business relationships, network with industry experts and discover the trends and innovations driving the fine and speciality chemical industry forwards.

Valmet to deliver a new digester top separator to Södra Cell’s Mönsterås Mill in Sweden

Valmet will deliver a new digester top separator to Södra Cell’s Mönsterås Mill in Sweden. The order is included in Valmet's orders received of the first quarter 2024. The value of the order will not be disclosed. The delivery is scheduled to take place in October 2024.

UPM Raflatac opens a new slitting and distribution terminal in Mumbai, India

UPM Raflatac opens a new slitting and distribution terminal in Mumbai, India. The new facility further improves service and quality to UPM Raflatac’s customers and strengthens the relationships in the region. “Our talented team has created a great workplace for our employees, a great facility to serve our customers and a great platform for growth. With the new modern facility, we can stock more material locally which will optimize lead times, enhance service, and help meet the diverse and dynamic needs of our customers,“ says Alan Wright, Senior Vice President, EMEIA Region, UPM Raflatac.

Mondi expands professional printing and converting papers portfolio from its Slovak mill

Mondi recently put a new slitting and rewinding unit into operation at its Slovak paper mill in Ružomberok. The equipment allows for an extended capacity in narrow reels thus complementing Mondi’s portfolio offering. “We want to give our customers supply security for their paper needs in folio and various reel widths and for this we needed to extend our narrow reel capacity,” explains Bernhard Cantzler, Marketing and Sales Director at Mondi Uncoated Fine Paper.

BW Converting at Tissue Summit Brazil

With high pulp costs and scarcity of operator talent, Brazilian tissue converters are on a quest to boost capacity, reduce costs and simplify operations. BW Converting Solution’s Hygiene division will present its suite of next-level technologies at Tissue Summit Brazil that harness the power of automation to operate more efficiently and cost effectively, with a reduced environmental footprint.

Toscotec to replace Yankee and steam plant at Papeco in France

French tissue manufacturer Papeteries du Cotentin (Papeco), purchased a TT SYD Steel Yankee Dryer and a complete high-performance steam and condensate plant from Toscotec to fully replace their existing cast iron dryer and steam system on PM3 at their Orval sur Sienne mill in Normandy. The project includes modifications to the machine for the new steam system and it is planned for start-up in the third quarter of 2024.

SCA to increase kraftliner prices by €80 per tonne

SCA increases the prices on white and brown kraftliner in Europe by €80 per tonne. The new price is valid from April 1, 2024.

“We see an improved and solid demand in the market for kraftliner with a good balance in the supply chain. The continued cost pressure is evident and must be managed to safeguard stable supply of sustainable kraftliner,” says Mikael Frölander, Vice President Marketing and Sales at SCA Containerboard.

Mondi: Collaboration makes release liner production waste more circular

Mondi has improved the circularity of material flows in two release liner production sites in Germany and the Netherlands. 95% of the production waste is now used as secondary raw material for other industries, thanks to its strategic partnerships. By collaborating closely with industry stakeholders along the value chain, Mondi has tackled the siliconised and coated paper waste produced at its release liner plants in Jülich, Germany, and Heerlen, Netherlands. It is now repulped and valorised as secondary raw material in a range of other applications.

Voith boosts production quality and efficiency on Weig's BM 6 in Mayen with OnQuality

Board manufacturer Weig is relying on Voith's technology expertise to upgrade its BM 6 at the Mayen mill in Germany to stabilize production quality. Voith is not only supplying an intelligent quality control system (QCS) consisting of scanners, actuators and controls but will also ensure seamless integration into a PCS7 environment.

Metsä Group and Andritz are aiming for ambitious climate goals

Metsä Group and technology supplier Andritz have agreed to work together to reduce Scope 3 greenhouse gas emissions. Scope 3 emissions refer to emissions from the company's value chain and purchases, such as emissions during the sourcing of production equipment and raw materials and the transportation and use of manufactured products. The goal of the multi-year cooperation is to increase the effectiveness of emission reductions and to find completely new ways to reduce greenhouse gas emissions.