P3 5-6/2021 en

What Does it Mean ...

Cantilever Framing

Education Gap

The fascinating term “cantilever framing” can be found in the field of paper production. An explanation from Michael Otto, Head of Press Section at Voith GmbH & Co. KGaA.

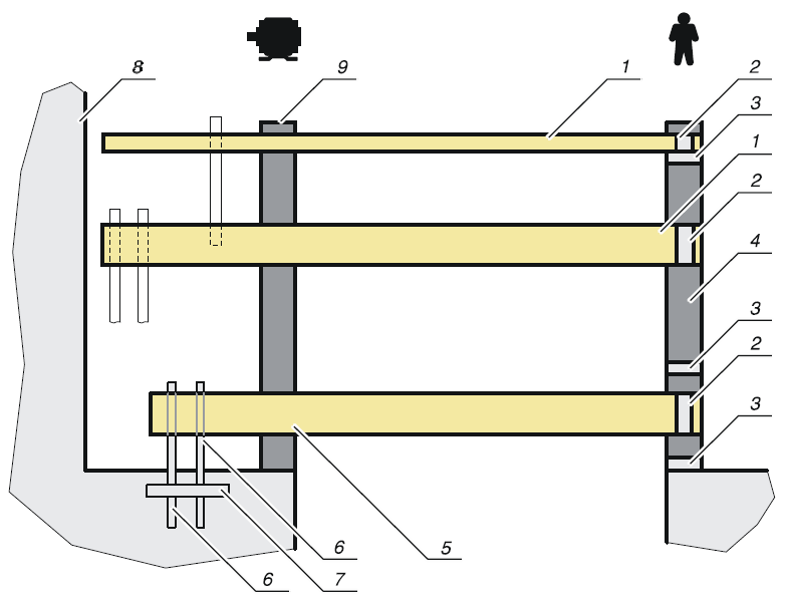

Cantilever framing: Structure (sketch).

Some of the fabrics in the wire and press sections are endless belts. With a so-called cantilever framing, a fabric can be inserted into the machine in this way. In this case, the framing on the front side is closed during operation in order to absorb the static and dynamic forces.

For a fabrics change, connecting elements, so-called intermediate pieces, are removed on the front side. This creates openings in the - front side frame through which the fabric can be drawn into the machine. A cantilever construction fully supports the framing parts on the front side, including their attachments such as rolls and brackets. The forces occurring on the front side framing are transferred by the transverse cantilever beam via the drive side framing and tie rods into the ground. As soon as the fabric has been retracted, the openings on the front side are closed again with the intermediate pieces and the operating condition is restored.

Legend

- Upper crossbeam (cantilever)

- Hydraulic cylinder

- Intermediate piece

- Front side framing

- Lower crossbeam (cantilever)

- Tie rod

- Floor anchorage

- Building

- Drive side framing