P3 7-8/2022 en

Smurfit Kappa & Pelipal

Every 4th Truck With Packaging Material is Saved

Standards

The German company Pelipal, headquartered in Schlangen (East Westphalia), is a European manufacturer of bathroom furniture and mirror cabinets, which are marketed as high-quality design furnishings as well as take-away furniture. For the packaging of the current product range, the company was looking for optimized cardboard packaging material. It is to be processed on an existing continuous packaging machine with minimum material input. Together with the packaging specialist Smurfit Kappa, a solution was developed that relieves both Pelipal and the end customers and brings significant efficiency advantages in various work areas and saves every 4th truck with packaging material.

The success story of the Pelipal group of companies began in 1906 with the founding of a construction and furniture joinery. Today, the group has around 550 employees at its headquarters and at another state-of-the-art production site in Eisenberg (Thuringia) and has an international sales network with branches and partners in 15 countries. Pelipal offers a wide range of bathroom solutions from value-for-money to high-quality, multi-award-winning luxury design bathrooms, appealing to a wide variety of target groups. Pelipal's sales channels include furniture retailers, DIY and online retailers, and sanitary ware retailers.

“Smurfit Kappa has worked with us to further develop and consistently optimize packaging”

For the plant in Eisenberg, where the takeaway furniture is produced, there was a need for an optimized packaging solution. To this end, production managing director Ulrich Henning consulted closely with Smurfit Kappa, which had already designed the first continuous-process packaging machine for Pelipal some 15 years ago. “Smurfit Kappa worked with us to further develop and consistently optimize the packaging,” says Ulrich Henning, looking back on the total 20 years of cooperation. “Whereas we initially required a storage area of 900m2 for over 500 different cardboard boxes and blanks, today it is only 300m2 of storage area that needs to be provided for the packaging machine.”

Smurfit Kappa is not only a manufacturer of packaging materials made of paper and cardboard, but also offers holistic customer advice on packaging and machine concepts. In this way, customers such as Pelipal receive a comprehensive recommendation on the perfect interaction between the board cutter and the most suitable packaging material and the associated logistics.

In order to meet Pelipal's updated product portfolio in Eisenberg and the need for high cycle rates combined with maximum flexibility in terms of packaging shapes and sizes, Smurfit Kappa developed a solution based on two components:

The existing board slitter has the prerequisites to process the zigzag-folded continuous corrugated board recommended by Smurfit Kappa and delivered on pallets. This works for product cartons of a wide range of formats and sizes in both small and more substantial units. Changeover time to another size is only a few minutes. The small amount of waste produced during automated cutting of the cartons does not have to be disposed of, but can be used as filler and buffer material in the carton to protect the goods. The solution with continuous corrugated board is significantly cheaper and more flexible than purchasing prefabricated cardboard boxes, which often had to be purchased in minimum quantities in the past and also took up larger storage areas.

Whereas Pelipal previously had to keep a costly stock of over 500 individual cardboard boxes in various formats, these problems have been eliminated by using continuous corrugated board. In addition to reducing material costs, packaging purchasing, storage space utilization, and packaging and handling time were significantly improved, enabling “just-in-time” packaging.

Further optimization: The secret of Pelipal's new continuous corrugated board

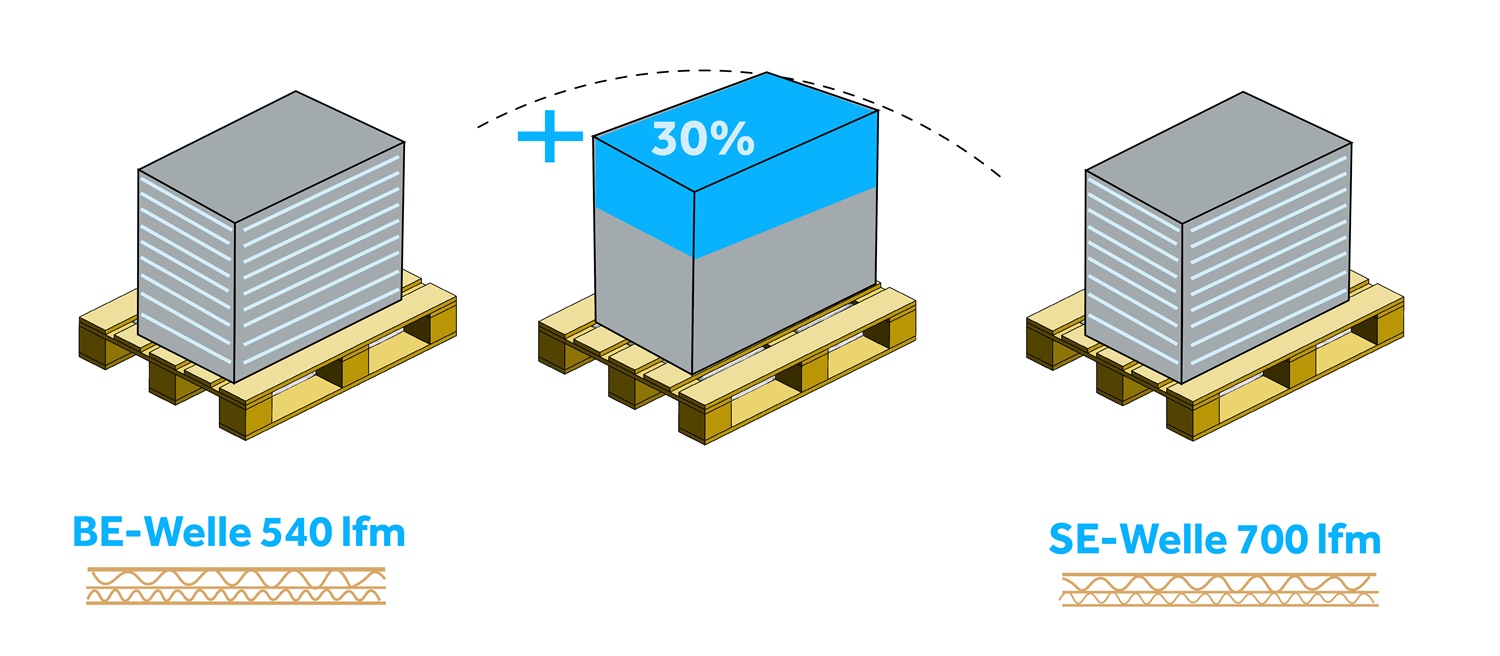

After the advantages of the change to continuous corrugated board at that time, a further optimization has now been implemented. The BE profile previously used has been replaced by a significantly lower SE-profile. The now flatter SE-profile significantly reduces the height of the palletized continuous corrugated board and thus increases the quantity per pallet, which of course has a direct effect on further optimization of the required storage space as well as the extension of production runs.

In addition to reducing the volume, the new SE-profile cannot only present the same physical properties of the BE-profile in terms of puncture, bursting and edge protection, but at the same time it improves the stability of the edge protection by a further 5%. Improved restoring forces in parallel improve handling when folding, filling and closing the carton.

For transport, the changeover from the BE- to the SE-profile thus has an enormous volume advantage: Whereas 540 linear meters used to fit on a pallet, it is now 700 linear meters. This results in an advantage of almost 30 percent. For Pelipal, this means a saving of every fourth truck in the supply of corrugated board.

This relieves the environment through reduced CO2 emissions, while at the same time process costs are noticeably reduced through lower warehouse traffic with larger safety stocks.

Paperboard made from FSC-certified paper

Another argument in favor of Smurfit Kappa's continuous corrugated board is that it is manufactured from 100 percent FSC-certified paper. All cardboard is fully biodegradable under natural conditions. Since Smurfit Kappa produces its own papers, the company can offer a high level of supply security, especially in the current times - a very important factor for customers.

Ulrich Henning: “We have trusted in the joint cooperation with Smurfit Kappa for over 15 years and are very satisfied with the company's solutions. Smurfit Kappa always gives us important impulses that can be implemented pragmatically. In this context, even small adjustments to the packaging often have major advantages in terms of efficiency and profitability, which in the end not only benefits Pelipal and the end customers, but also the environment.”