P3 3-4/2021 en

PTS Conference

“Paper & Board for Food Contact”

Events

The established PTS conference “Paper & Board for Food Contact” took place on March 2nd and 3rd, 2021 - this time with two innovations. On the one hand the conference language was English and on the other hand the event was organized as an online session. These changes offered the participants an innovative program, diverse topics and contributions from international experts.

Fig. 1: Origin of conference participants by country.

The field of participants was international: Dr. Harling and Dr. Kleebauer welcomed 70 participants and speakers from 15 countries (D, F, ES, DK, Israel, USA, India, CZ, AT, CH, Pakistan, BE, FL, NL, SWE).

With the support of Streampate, the PTS seminar room in Heidenau became a live studio for two days, from which the moderation and lectures were broadcast. In addition, the speakers were connected online to give their presentations and take part in the panel discussion with images and sound - from Denmark to Pakistan.

The recognized international speakers from science, authorities and business provided updates and impulses with the usual good discussion potential.

Current FCM Legislative Developments in Europe and Germany - An Update

Katharina Adler, Federal Ministry of Food and Agriculture (BMEL)

Ms. Adler introduced the legal basis in Food Contact Materials (FCM) law and provided information on the current status of the evaluation and revision of the EU FCM regulations.

The Commission will review food contact materials legislation to improve food safety and public health (in particular by reducing the use of hazardous chemicals), promoting the use of innovative and sustainable types of packaging using environmentally friendly, reusable and recyclable materials and contributing to a reduction of food waste. In addition, as part of the initiative for sustainable products announced in the Action Plan for the Circular Economy, it will prepare a legislative initiative on reuse in the field of catering services to replace single-use food packaging, single-use cutlery and cutlery with reusable products (“Farm to Fork” Strategy May 2020). The first proposal for the revision of the FCM rules is expected for the end of 2022.

The aim is to shift the focus to the end material and better address the properties of all end materials and products. The migration of all potentially migrating substances (NIAS) should be considered, not just that of the starting substances (IAS). Safety levels and rules are to be defined as to how this is achieved (e.g. through EU legislation or self-regulation), GMP rules are to be strengthened. A graduated approach based on different hazard classes (public risk assessment vs. self-assessment) is being considered: 1. CMR, endocrine disrupting substances, persistent, bioaccumulative, toxic; 2. substances with specific properties (nano), 3. rather harmless, low migration. Ms. Adler also pointed out the influence of accompanying legislative initiatives such as the “EU Chemicals Strategy for Sustainability” and for a toxic-free environment, which provide for a ban on the most harmful chemicals in consumer products (including food contact materials). Safer and more sustainable FCM should be promoted. The evaluation of the safety of reuse and recycling as well as the exclusion of risks from contamination should be carried out according to clear rules. Coherence and consistency with environmental legislation is a stated aim. Furthermore, the Commission plans to regulate the requirement of declarations of conformity for all types of FCM to enact.

With regard to the Plastics Ordinance 10/2011, the 15th Amendment Ordinance introduced that for FCM for repeated use, the migration from the first to the third test must not increase. In addition, rules have been introduced to check the transfer of components from food (processing) plants or equipment as a whole. Other possible changes relate to the deletion of the entry of natural wood flour and wood fibers as plastic additives due to a lack of information, particularly with regard to toxicological assessment (EFSA 2019 statement). “Bamboo articles” such as coffee to go containers, which are melamine resin articles with added bamboo, are not marketable according to Regulation 10/2011, since, according to EFSA, bamboo is not a wood and is therefore not an approved additive / filler for plastic FCM.

National projects such as the “Printing Inks Ordinance” and the “Mineral Oil Ordinance” are still being coordinated internally by the federal government and are both being pushed forward, as the Commission has not promised any European measures.

The new Council of Europe FCM-Resolution CM / Res (2020) 9 on the safety and quality of materials and articles for contact with food

Dr. Ingo Ebner, Federal Institute for Risk Assessment (BfR)

Dr. Ebner presented the Council of Europe resolution published on October 7, 2020 for FCMs that are not regulated by specific individual measures. The Council of Europe resolution FCM supplements EU and national regulations and fills a regulatory gap. The aim is to improve consumer protection against FCM substances and to contribute to the harmonization of regulatory approaches across Europe.

The resolution is supplemented in the appendix by “Guidelines for food contact materials” - and accompanying “Technical Guidelines” to cover material-specific questions and for conformity documentation / declaration of conformity. In addition to specifications on substances used and their risk assessment, guidelines for labeling, traceability, GMP, declaration of conformity and accompanying documents as well as conformity tests are given. A specific resolution on FCM made of paper and cardboard is about to be published.

The new ECMA Good Manufacturing Practice Guide - Approach and provided guidance

Jan Cardon, ECMA - The European Carton Makers Association

Hot off the press Jan Cardon presented the new ECMA GMP guidelines of the European cartonboard manufacturers' association. This is based on common standards of the food industry such as the FSSC 22 000 and the BRCGS Global Standard Packaging Materials Issue 6. Many helpful flow diagrams and decision trees guide through the complex of good manufacturing practice, allow to identify critical control points based on the HACCP concept and to derive measures at crucial points in the cardboard manufacturing process.

Influence of relative humidity on the transfer of volatile organic compounds from paper and board to Tenax®

Nancy Wolf, Sylvie Hoyer, Prof. Dr. Thomas Simat, TU Dresden - Chair of Food Science and Food Contact Materials

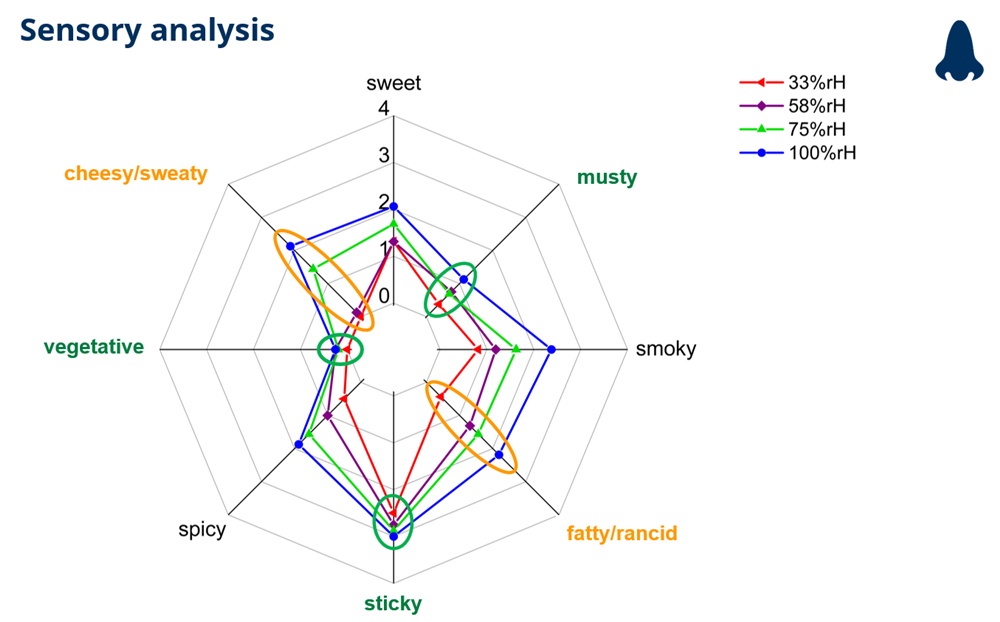

Interesting comparisons of migration studies on the simulant Tenax® as well as sensory tests of paper under the influence of the relative humidity (RH) were presented by Ms. Wolf from the TU Dresden / AK Simat. The exemplary results of the migration tests on corrugated cardboard base paper (testliner) also showed that “wet dogs” smell stronger than “dry dogs”: significantly more volatile organic substances (VOC) were released at higher humidity, in particular ≥ 75% rH. A completely different sensory impression was also created when the humidity changed. In order to evaluate the importance of the knowledge for future test strategies, investigations of further types of paper are planned.

EuPIA Guidance on Migration Test Methods for the evaluation of substances in printing inks and varnishes for food contact materials

Werner Oechsle, European Printing Association - EUPIA

How to check the safety and migration of substances from printing inks and varnishes for FCM, Werner Oechsle presented on the basis of the EUPIA guidelines, which were last updated in August 2020. This industry guide addresses both printing inks for non-direct and direct food contact (DFC). He recommends testing under worst-case conditions (using a screening approach); which, however, is not intended as a substitute for the conformity test of the final printed food contact materials. The following approach is suggested in the test hierarchy: “Worst case” - calculation, modeling of the migration, accelerated migration with test simulants and, if the conformity is still unsure, migration test with the real food in the planned use of the paints and varnishes. The printing test pattern to be generated should preferably reflect the final packaging application that will be used in the field. This should be done as precisely as possible, taking into account the printing and drying process, the weight of the film and the type of substrate. When selecting the test conditions, the type of substrate (cardboard, film), the contact (direct / not direct) and the food properties (fatty, moist, dry) are taken into account in order to select the appropriate simulant and contact time.

Optimization of packaging through software-based prediction of shelf life

Dr. Matthias Reinelt, Fraunhofer Institute for Process Engineering & Packaging IVV

How software support can be used to develop new packaging solutions was demonstrated by Dr. Reinelt from Fraunhofer IVV. The varied interactions between the packaged goods and the packaging material, which cause parameters such as loss of aroma, oxidation, outgassing, gas exchange required for breathing, microbiological growth and moisture, can be represented in algorithms and the influence of the various levers can be considered and an optimum can be recommended. Lengthy storage attempts of several months can be avoided by creating a digital twin.

Titanium Dioxide - Update on Classification and Possible Impacts

Dr. Martin Erben, Venator Germany GmbH

An update on the classification of titanium dioxide and the resulting effects was provided by Dr. Martin heirs. In September 2017, ECHA's Risk Assessment Committee (RAC) proposed the classification of TiO2 as suspected carcinogen (Cat. 2) if inhaled. The Commission accepted the classification proposal on October 4, 2019 and it was published in the Official Journal in February 2020 after more than 2 years of regulatory deliberations. From October 1, 2021, the classification of TiO2 will be binding after an 18-month transition period. This now results in various labeling regulations for titanium dioxide as a solid itself, but also for liquid mixtures and solid mixtures containing TiO2 with a content of titanium dioxide particles of 1% or more, which have an aerodynamic diameter of 10 µm or less. The classification as carcinogenic by inhalation only applies to mixtures with a relevant aerodynamic diameter in powder form. The classification of the mixtures is based on workplace exposure regulations, which are simulated using a rotating drum or in a drop tower in order to simulate the behavior of titanium dioxide powder (EN15051). The detection takes place by filter, cascade impactor, laser diffractometry or ToF spectroscopy. The classification as a CMR substance in powder form also has an impact on regulations in the use of cosmetics and toys, as well as on the admissibility of eco-labels - CMR substances are mostly excluded here.

The new Danish Regulation: PFAS ban in paper & board

Mette Holm, Ministry of Food, Agriculture and Fisheries, The Danish Veterinary and Food Administration

Due to toxicological concerns, a possible health risk and known environmental persistence, Denmark has been discussing and preparing a ban on per- / polyfluoroalkyl substances for food contact materials, especially in paper and cardboard, since 2015. Mette Holm reports on this. In 2019, the ban on using PFAS for FCM made of paper and cardboard was passed, which came into force on July 1, 2020 (681/2020). Due to the ubiquitous distribution of PFAS - including from paper recycling - one could not orientate oneself to the very low toxicologically acceptable values ??for organic perfluorocompounds when setting a limit value, but had to use 20 µg PFAS, measured as Total Organic Fluorine (TOF) / g Paper, to set an indicator value for an unavoidable background pollution. Papers with a functional barrier that prevents the migration of PFAS into food are exempt from the ban. However, there is no reliable analytical method for the PFAS class, which comprises over 4,500 different individual substances, neither as a substance nor as a migration method. The enforcement and legal security of this requirement was therefore questioned in lively discussions by the conference audience. According to Mette Holm, there are enough PFAS alternatives to make the papers grease-proof.

Total organic fluorine (TOF) analysis for PFAS impurities determination in recovered paper grades

Sandro Kuttig, Eurofins Umwelt Ost GmbH, Freiberg

Sandro Kuttig continued the PFAS discussion with his lecture on Total Organic Fluor (TOF) analysis for determining PFAS as a sum parameter. For this it is necessary to differentiate between inorganic and organic fluorine compounds. The determination takes place via combustion and subsequent fluoride determination by means of ion chromatography. A large discrepancy between the individual determination method with 22 recorded PFAS individual substances and the TOF determination showed that only a small percentage of 0.00004-11.3% was recorded with the specific methods compared to the TOF method. Also, some matrices, especially those with a high content of inorganic fluoride, cause interference in the TOF methodology, which leads to indeterminability, even though PFAS were included.

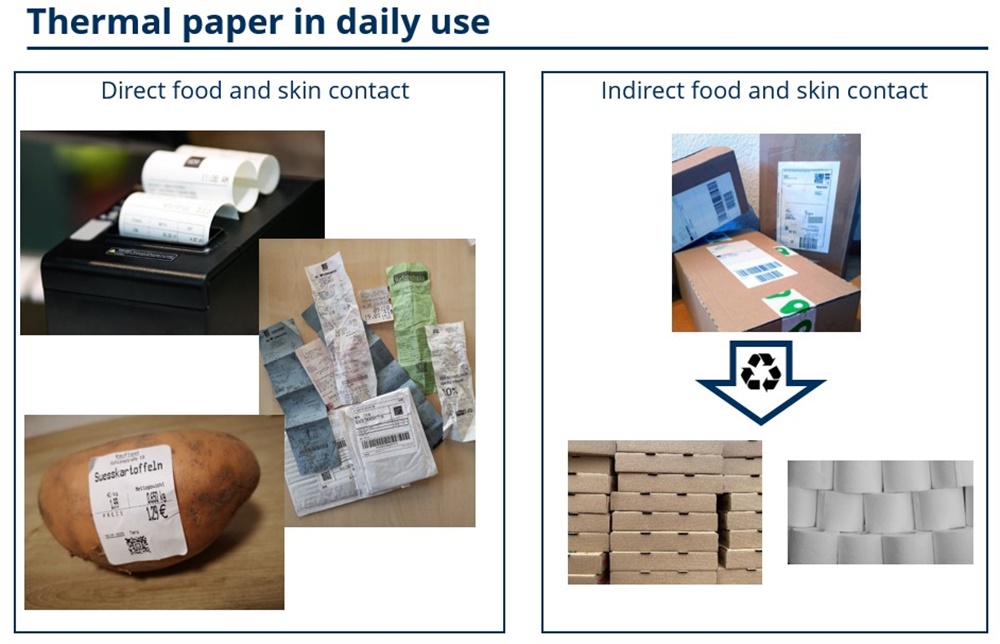

Thermal developers - BPS and other BPA Alternatives

Annemarie Greb, TU Dresden - Professorship for Food Science & Consumer Goods

Ms. Greb reported on systematic, observational studies by the TU Dresden from 2015 to 2020 on the replacement of bisphenol A in thermal papers (examination of approx. 100 samples per year). As early as 2015, Pergafast 201's share of the developers used was over 30% and exceeded the BPA share for the first time in 2019. With the ban on BPA in the EU, the proportion of BPA rose from under 15% (2015 - 2019) to 40% in 2020, although Pergafast 201 still makes up the majority with 45%. In particular, the thermal papers are recycled via parcel stickers and adhesive labels, while receipts are partially sorted out. For BPA and BPS it has been shown in studies by the food control that these recycled fibers contaminate. This year, BfR Recommendation XXXVI includes a restriction of 0.05 mg / kg for the transition from BPS from recycled paper to food in addition to that for BPA. However, for most BPA replacement developers only incomplete information about persistence and human and environmental toxicology is available. There are also thermal papers that do not use any developer substances. It won't get boring here, says Annemarie Greb.

Multi-client project BPS, BPA, PERGAFAST 201, PFAS

Max Schneider, Paper Technology Foundation (PTS)

Already unsuitable recovered paper qualities can lead to the indicator level for PFAS (TOF) being exceeded and thus result in the requirement for a functional barrier, reported Mette Holm. BPA and its substitutes BPS and Pergafast put a strain on the waste paper cycle, says Annemarie Greb. In order to get an overview of the entry of these substances into the paper cycle through different types of waste paper, the PTS has therefore launched a multi-client project. Max Schneider presented the details of this project. In addition to the content and migration measurements, the result should be a conclusion about the used paper qualities and their contamination with the examined substances BPA, BPS, Pergafast and PFAS (TOF). The results are made available exclusively in anonymized form and exclusively to the project participants. Participation in the project is open to all interested paper and processing companies and is still possible until the beginning of June 2021.

Aluminum release of FCM - outcome of research work

Antje Kersten, TU Darmstadt - Department of Paper Manufacturing & Mechanical Process Engineering (PMV)

Limiting the release of aluminum from paper FCM into food was included in the BfR Recommendations XXXVI, reported Antje Kersten. When testing according to EN 645 (cold water extract), however, a few important things should be observed when preparing the sample, in order not to include coating particles from e.g. kaolin or to obtain incomparable results. Influences such as pH value and ionic strength of the water used, sample size reduction and filtration require more precise details. Comparisons with food migrations showed where reality and simulation of aluminum release match or differ. The release of aluminum is only relevant if the paper comes into contact with moist and especially acidic foods foreseeable. The findings are to be incorporated into the revision of EN 645 standards as well as a separate aluminum regulation.

Drinking straws made of paper - technical issues

Dr. Imke Cravillon, DREWSEN SPEZIALPAPIERE GmbH & Co. KG

Dr. Imke Cravillon presented the technical challenges in the production of paper straws. The Single Use Plastics regulation gave these paper alternatives a boom. The release of MCPD, DCP, mineral oil hydrocarbons, PAA and photoinitiators have already been a challenge in the past. There are also some technical performance details that need to be addressed, such as delamination in the drink, premature softening, outgassing of carbonated drinks and an unpleasant mouthfeel on the lips. This must be optimized so that the product is accepted by customers and consumers. A plant-based coating could help here.

Chloro propanols release from FCM paper: recent results from an official control laboratory

Lydia Richter, Chemical and Veterinary Investigation Office CVUA, Stuttgart

Lydia Richter from CVUA Stuttgart also reported results on the release of MCPD and DCP from straws into the cold water extract (EN 645). Here, slightly less than half of the paper straw samples examined (6 of 13) did not comply with the guideline value of the BfR recommendation for MCPD. With a total of more than 108 paper samples as well as baker's bags, party plates, serviettes, kitchen towels or muffin molds, this MCPD guide value was exceeded in only 6%, while DCP could be determined in only 3 samples (3%). The paper industry is well on the way to minimizing this.

Halal production of paper and board - requirements and certification

Farhan Tufail, Halal Certification Services GmbH

Farhan Tufail gave the entertaining final lecture live from Pakistan. He explained when a product is "halal". In a nutshell: "Everything that is not explicitly forbidden is allowed". For example, animals that are not properly slaughtered according to Islamic laws and the ingredients obtained from them are prohibited. Packaging material must be checked for the absence of hidden ingredients such as animal stearates, which are used in the manufacture of plastic containers. According to Mr. Tufail, packaging material manufacturers will soon be inundated with Halal inquiries as awareness and Halal certification grow.

Fig. 5: Sensory impression of corrugated cardboard base paper (testliner) as a function of the relative humidity (rH).

Fig. 7: Titanium dioxide: classified as a solid and a category 2 carcinogen - what does that mean for FCM?

Fig. 8: Pizza box packaging can be made grease-proof with PFAS - the ban in Denmark makes alternatives necessary.

Author: Dr. Antje Harling, Papiertechnische Stiftung (PTS) Heidenau

Editor: sbr

Images: Pixabay / PTS [1]; PTS [2, 3, 6a/b]; Nancy Wolf, TU Dresden [5]; Pixabay [4, 7, 8, 10]; Annemarie Greb [9]