P3 7-8/2021 en

Loftware

How Manufacturers are Digitizing Their Labeling Solutions

Package Printing

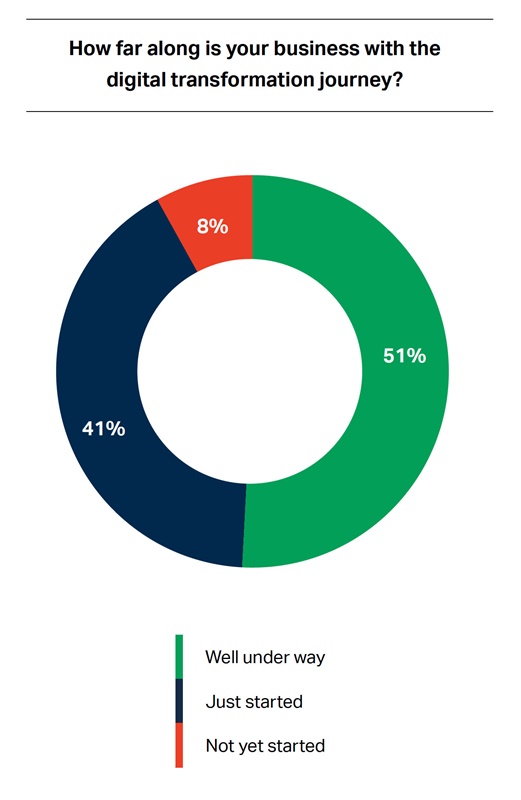

Over 50 percent of the companies have already modernized their production processes or are at least already well advanced. However, 41 percent are just at the beginning of digitization, while eight percent have not yet started.

The modernization of enterprise resource planning is also impacting labeling solutions, and this is where the cloud plays an essential role. It facilitates the integration of various business applications and thus offers companies decisive advantages in the digitization of their labeling processes.

A current study by Loftware of 300 IT managers from manufacturing companies in Germany, France, Great Britain and the USA shows that organizations still face major challenges when it comes to digitization. According to this, over 50 percent of the companies have already modernized their production processes or are at least already well advanced. However, 41 percent are just at the beginning of digitization, while eight percent have not even started.

Over 50 percent of the companies have already modernized their production processes or are at least already well advanced. However, 41 percent are just at the beginning of digitization, while eight percent have not yet started.

This sweeping trend in IT modernization is also having an impact on labeling. When large companies update their ERP system, this, among other things, leads to them subsequently modernizing their labeling systems and often migrating to or implementing a new standardized global labeling solution.

The cloud is the other major driver driving the enterprise labeling transition. 18 percent of the survey participants have already moved their entire IT infrastructure to the cloud. And another 37 percent have moved most of their IT infrastructure to the cloud.

However, there are also skeptical voices among the study participants on the subject of the cloud. 27 percent fear a loss of performance and 26 percent expect problems with the integration with other company systems. Therefore, companies should rely on a trusted labeling solution that has already proven its efficiency in practice and easily supports comprehensive integration with ERP software such as SAP and Oracle as well as manufacturing execution systems (MES) and warehouse management systems (WMS).

Integration in business solutions is a must

Such an integration option is of central importance, because it allows companies to use existing business processes and important data sources without the users having to be retrained. Such integration also increases the accuracy and consistency of data because it comes from a single trusted source. In this way, companies reduce the risk of labeling errors and avoid the resulting disadvantages such as production stoppages or delays in transport.

Thanks to efficient integration into ERP solutions and other systems, companies can also automate work processes, adapt individual customer or industry requirements and thus increase the efficiency of labeling.

The use of cloud technology helps with this integration. One of the most important catalysts for this is cloud-to-cloud integration: a cloud business system is integrated into another cloud business system. Companies should make sure that the integration of their labeling system is as easy as possible thanks to cloud connector APIs.

Cloud-based labeling solutions offer clear advantages

The companies surveyed most frequently switch to the cloud in the following areas: Enterprise Resource Planning (42 percent), Supply Chain Management (40 percent) and Sales & Operations Planning (40 percent).

There is still a long way to go, but the trend towards the cloud in the manufacturing industry cannot be overlooked. And cloud-based labeling is an integral part of this ongoing migration. This enables companies not only to rationalize and globally scale the labeling process, but also to save considerable costs that they would otherwise have to spend on maintaining the expensive IT infrastructure. This is confirmed by the questioned IT managers from the manufacturing industry: 31 percent see savings potential in the use of the cloud for hardware and 29 percent for IT services.

One of the major advantages of cloud-based labeling solutions is their greater flexibility. Regardless of whether the labels are needed in the warehouse, in the factory or in another facility, those responsible with the appropriate authorizations can create or update them from any location via a browser. This greater flexibility also paid off during the pandemic, for example, when home office was compulsory in many regions. In this way, a cloud-based labeling solution ensures that business operations can be maintained even in difficult times.

In addition, this approach offers better collaboration: By extending labeling to partners and suppliers, they have access to correct label data, so that costly and time-consuming re-labeling due to faulty labels is reduced throughout the supply chain. Promoting consistency in the supply chain also helps prevent product counterfeiting and diversions. With a cloud-based labeling solution, companies can also improve relationships with partners in the supply chain. After all, around 30 percent of the companies surveyed expect this from a modernization of their labeling system.

Comply with international safety standards

The advantages of a modern labeling system are also evident in relation to compliance with global safety standards. With a range of input parameters, users can create product labels that correspond to several international legal systems and contain relevant information for safe and smooth transport.

Such a solution offers the possibility, for example, of creating warning notices in several languages depending on the country of origin and destination, or barcodes that companies can use to track their products. In addition, users can dynamically place images and pictograms on the labels and, if necessary, even include additives and safety instructions.

Into the future with a cloud-first strategy

The time has come for a more centralized approach to labeling. Companies need uniform management of administration and label templates across the entire supply chain. They need to be able to grow and scale easily. Centralized, cloud-based technology reduces the complexity and problems associated with installing and maintaining labeling systems. This gives companies immediate access to the functions they need, optimized administration and more security in terms of access and transparency.

As there are many labeling operations across the supply chain and the integration of this labeling is of great value, it is becoming increasingly important to involve other partners as well. A cloud-based labeling solution is best suited for this.

In order to be competitive in an increasingly networked world where high quality products have to be delivered faster and to more markets, traditional labeling methods with manual processes and different printing solutions are unsuitable. Companies should completely digitize and standardize the process of product labeling and integrate it into manufacturing and logistics systems using a cloud-first approach. This not only improves quality and responsiveness, but also lowers costs and shortens the time to introduce new products.