P3 5-6/2021 en

Pulp Analysis

Hallsta Mill - The Biggest PulpEye User in the World

Concepts & Solutions

Holmen’s paper mill in Hallstavik, Sweden, has received its fifth PulpEye online pulp analyzer, making the mill the biggest PulpEye user in the world. The first one came in 2006 and the fifth has just arrived at the mill. Which benefits do online pulp analyses give to pulp- and papermakers? How come that a fairly small Swedish high-tech company has established itself globally and why has the Hallsta Paper Mill for the fifth time chosen pulp analysis equipment from PulpEye?

Holmen Paper’s mill in Hallstavik has just installed its fifth PulpEye.

“We were five enthusiastic engineers in Sweden with a solid background in measurement of pulp qualities online who founded the PulpEye company in 2002,” says Öjvind Sundvall, one of the founders and MD of PulpEye. “Based on our experiences we were convinced that it ought to be possible to develop better technologies for measuring important pulp properties online compared to the ones existing in those days. Therefore, we decided to set sails and together with users develop our own solution starting with analyzer modules for fibre, shives and freeness measurements. Since then more pulp analyzer modules have been developed and installed in both chemical and mechanical pulp mills as well as in OCC and MDF plants worldwide.”

“The first PulpEye customer installation was in 2004 and the historical first customer was Rottneros buying a PulpEye with modules for online measurement of fibre, shives and freeness as base functions. This first installation is after seventeen years still running. The mill has since then done comprehensive production investments as well as installed additional PulpEye equipment and modules.”

Hallsta Paper Mill, an early user of PulpEye analyzers

Another very early PulpEye user is Holmen Paper’s Hallsta mill which already in 2006 bought and installed their first equipment. For many years the mill, located about 100 kilometres north of Stockholm, was one of Europe’s biggest newsprint mills, and in 1974 the mill had as many as eight paper machines. Since then it has changed quite a lot and today has two paper machines, the 8.6 m wide PM11 and the 8.5 m wide PM12.

In 1974 the mill was the first in Sweden to start production of TMP pulps and since a number of years the whole production is based on TMP pulps from fresh spruce. Like most producers of newsprint and similar printing grades the mill has had to develop and produce other paper products and today Hallsta Paper Mill is a big producer of papers for applications like books and magazines. It is also where many of Holmen Paper’s speciality products have been developed and to a large extent are manufactured. Paper from Hallsta Paper Mill is eco-certified, and brands produced are Holmen View, Trnd, Xlnt, Plus, Book, EpiqQ, Uniq, Gift, Pack and Note. The mill employs about 370 people.

“The Hallsta Paper Mill has a fifteen-year history with PulpEye and is with five installed units now the biggest user in the world of PulpEye analyzers,” says Öjvind Sundvall. “Now three analyzers are placed in the TMP plant and since 2009 there is one in the paper mill, analysing samples from both paper machines’ stock preparations. The fifth, connected with an RMEye unit for loading manual samples, is placed in the laboratory and is also used as a master for all online pulp analyzers in the mill.”

“Our existing pulp analyzers had for many years served us well but they were gradually approaching the end of their lifetime,” says Maria McGuinness, Production Engineer, TMP and Bleaching, at Hallsta Paper Mill. “A couple of years ago we therefore evaluated the different future replacement alternatives. We wanted a robust technology combined with flexible usage as well as good service and support and concluded that PulpEye was the pulp analyzer most suitable for our needs. We have just received our fifth PulpEye in the mill. So now we have a modern and efficient way of controlling pulp and stock quality.”

The PulpEyes in the TMP department are used to quality control of the pulp as well as of the reject handling. The one in the stock preparation is used to control the LC refining processes. All PulpEye analyzers are equipped with fibre, shives and CSF modules and in addition one analyzer in the TMP department is also equipped with a CrillEye module.

The importance of crill for strength properties

The CrillEye module is a good example of how research results obtained in a technical institute can be brought to market through cooperation with a commercial company and it is a story worth telling.

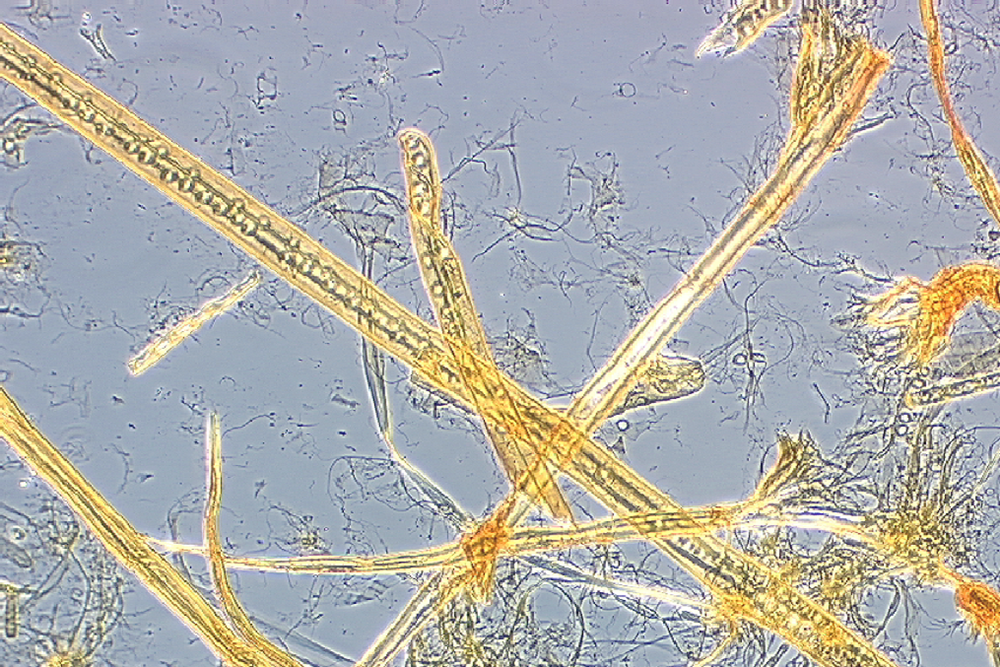

The existence of very fine fibrous material called crill has been known since the early 1960s. Crill is finely divided cellulosic material liberated during pulp refining. The crill particles are typically 0.25 micrometres in width and about a hundred times thinner than the fibres. Although only about one per cent of the weight of fibres and other particles in the furnish is crill, it can correspond to as much as fifty per cent of the total free surface area. This shows the importance of crill for the strength properties of pulp or paper.

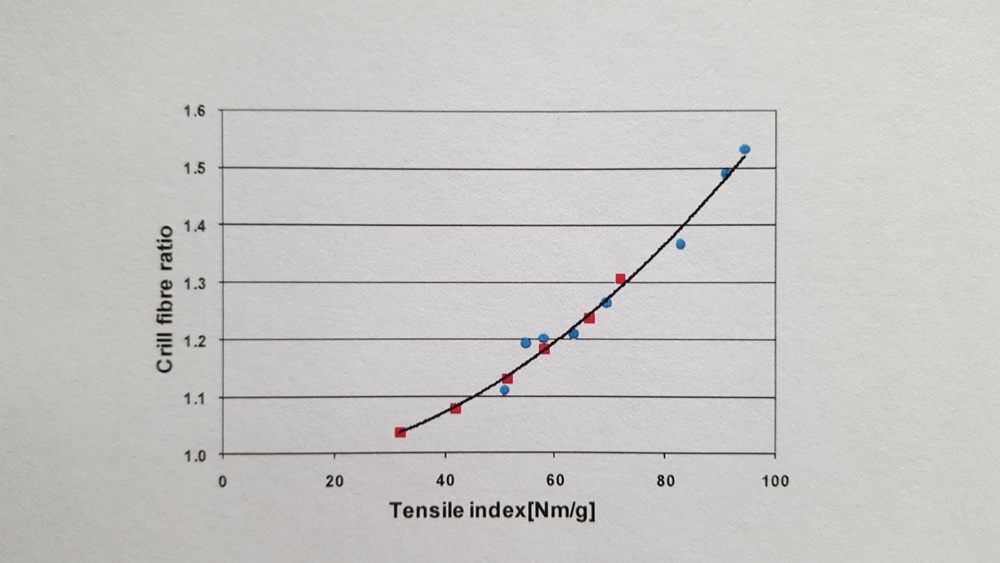

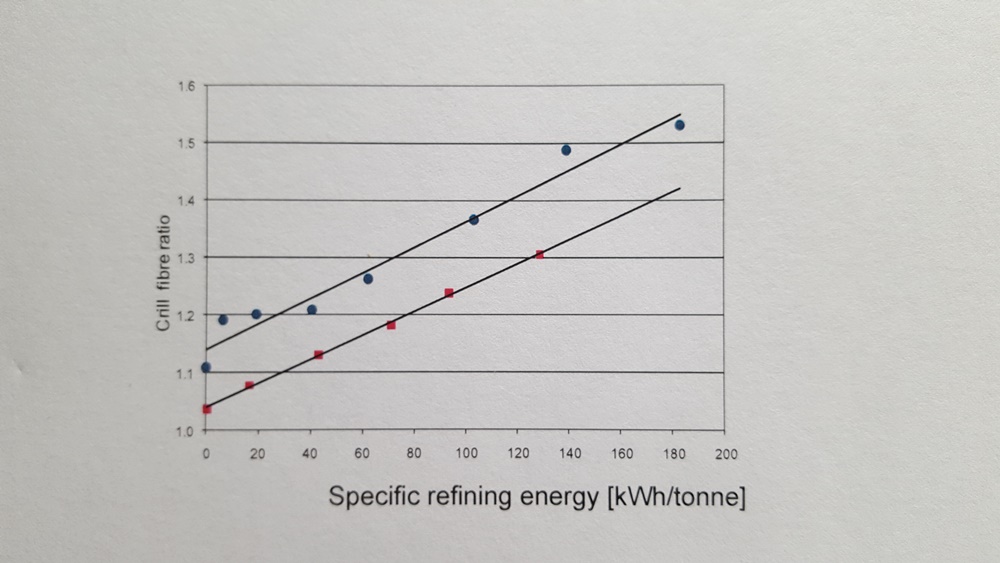

Research studies at former Innventia, now part of RISE Research Institutes of Sweden, showed that crill is the single variable having the strongest connection to paper strength. Laboratory results in Figure 1 show a strong correlation to paper tensile strength index. The more crill there are on and around the fibres, the stronger the paper will be. By measuring the amount of crill it is possible to pre-calculate the strength of the pulp and hence define the refining needed to optimise the amount of crill. The crill content of the pulp has a linear function of the specific refining energy applied as shown in Figure 2. This linearity makes managing crill content a simpler task.

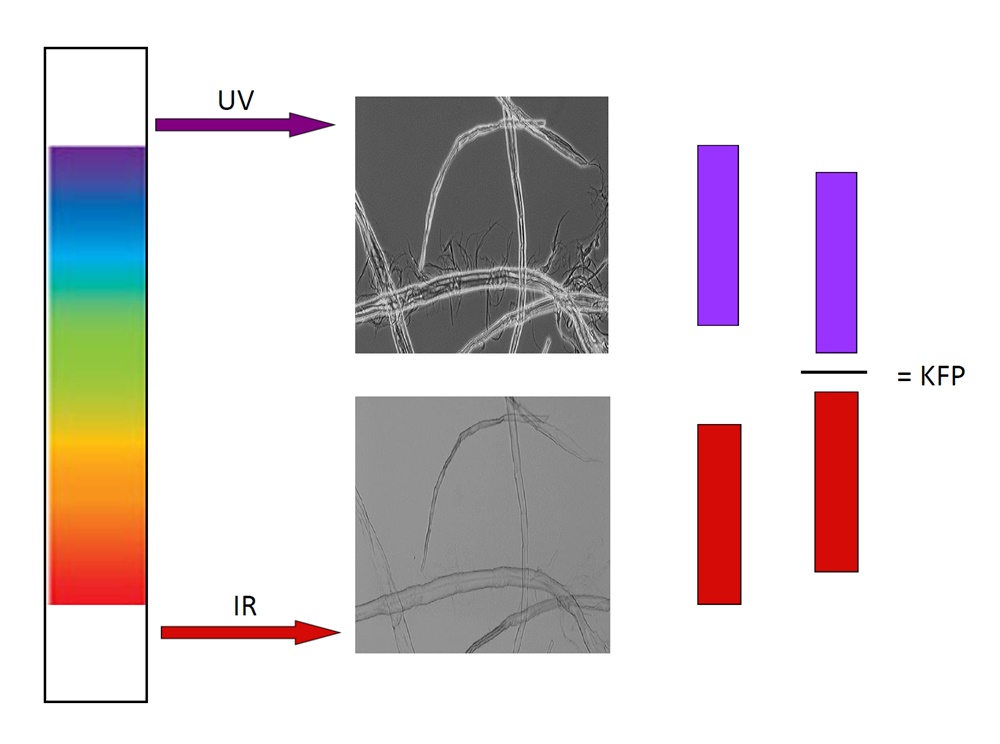

The crill measurement is based on the comparison of two optically measured surface areas by light absorption. It is adapted from the kappa measurement optical detection system. The total area of fibres and crill is measured with ultraviolet (UV) light. The total area of fibres only is measured with infrared (IR) light. The light absorption measurements are extremely fast, which is an advantage for online detection and measurement update speeds. The “crill variable”, KFP, is a concentration independent ratio, obtained when the fibre plus crill area (UV) is divided by the fibre only area (IR). The measurement can differentiate between crill particles that are detached from the fibres and those which are still attached. Figure 3 illustrates the measurement principle.

Modular fibre analysis system

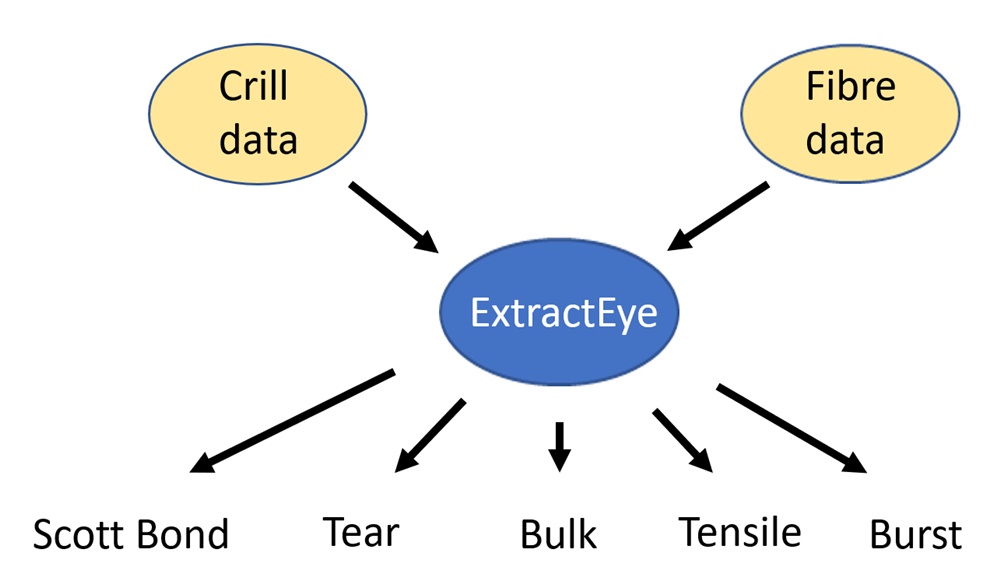

CrillEye is a measurement module of the modular PulpEye system. Data from PulpEye and crill data are fed into the ExtractEye calculation module where tensile, tear and burst strengths as well as bulk and Scott bond properties are calculated, as shown in Figure 4. This is done every fifth minute and the results are shown online to the mill operators on screens.

“At Hallsta we have a CrillEye module in one of our PulpEye units in the TMP plant”, says Anders Thorén, acting Mill Manager at Hallsta Paper Mill. “We bought this unit to start learning even more about the fibres and how we develop them in our process. “Old school” information isn’t giving us the full picture so with some more development and understanding of the CrillEye module we hope to open a new book of information.”

“Today most mills in the pulp and paper industry have a mill data base containing a huge amount of process and quality data from which ExtractEye can retrieve data for hundreds of variables and present a clear summary of how the process is running,” says Otto Lindeberg at Extract Information, the inventor of ExtractEye. “In mills using ExtractEye it continuously retrieves process and quality data important to board or paper manufacturing respectively. Process operators can follow calculated pulp properties and make necessary adjustments to keep the quality on specified targets.”

“In Hallsta mill, work is underway to build a process model with important parameters that affect quality outcome,” Maria McGuiness continues. “The model is intended to be used as an operator tool in the TMP plant to quickly find causes for deviations in quality outcome, and it contains both process data and quality data from PulpEye measurements. With the ExtractEye software, we see the opportunity to be able to look at more quality parameters at the same time, i.e. make more use of the data that is available today and thus better understand the cause of quality deviations.”

For mills producing any kind of pulp there is a package available from PulpEye, PulpOnTarget, in which ExtractEye retrieves data for fibre properties from PulpEye to calculate pulp quality data to give a corresponding overview of the pulp production. Pulp mills therefore install PulpOnTarget to get a good and always updated process overview to optimise the process as well as the product quality.

Fruitful cooperation with institutes and universities

“No one can come up with solutions to each and every problem and this is also true for PulpEye,” Öjvind Sundvall continues. “Apart from close cooperation with customers getting ideas for developments we are also cooperating with research institutes and universities bringing cutting edge technology to the market. Examples of such cooperation are with FP Innovations which resulted in analyzer modules for analysis of fibre wall thickness and for measuring vessel cells, with former Innventia for the CrillEye module and with RISE Processum in developing the DotEye module together with a number of pulp mills.”

“Having started on a quite modest scale, gradually supplying Swedish pulp, paper and board mills, our analyzer equipment is now used in sixteen countries worldwide. We are very grateful for the trust shown us by customers like Holmen Group and many others for their willingness to cooperate and bring new development ideas to us and hence to the market,” Öjvind Sundvall finishes.

The CrillEye module is increasingly used by pulp, paper and board producers to optimise the process and product quality.

Fig. 4: Using ExtractEye bulk, Scott Bond value, bulk, tear, tensile and burst can be calculated online from crill and fibre data.

Author: Sören Back, SB Kommunikation AB

Editor: sbr

Images: Holmen [1]; PulpEye [2-4]; RISE Research Institutes of Sweden [5-6]