P3 5-6/2022 en

Biofilms & Peroxide

Advances in Detection Technology Allow for Greater Material Efficiencies

Concepts & Solutions

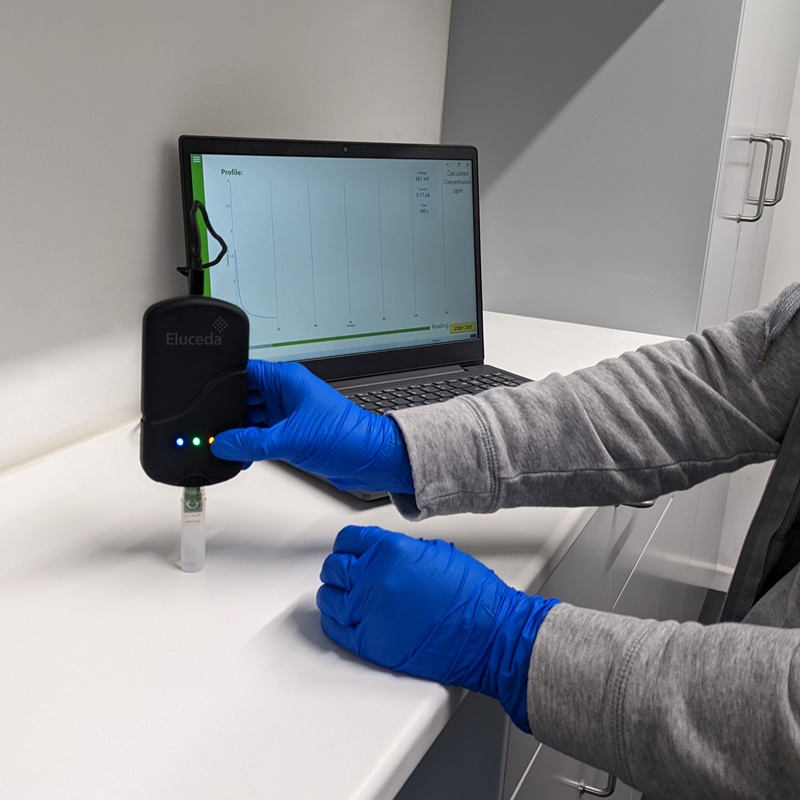

Eluceda’s testing solution uses its E-Sens™ digital reader in combination with a specialised electrochemical sensor.

Microbes that form biofilms in water systems are a significant issue for paper mills, causing damage to equipment and reducing paper quality. In order to combat this, biocides such as hydrogen peroxide (H2O2) are used, often in greater volumes than is necessary, so as to ensure that these microbes are removed. However, this approach can lead to inefficiencies and material wastage in a world of rising material costs and sustainability pressures. Advances in detection technology now mean that rapid, accurate and digital measurement of precise levels of both biofilm contamination and hydrogen peroxide levels is now practical, thus allowing for greater efficiency in H2O2 usage. Dr Ian Eastwood, Chief Technology Officer at Eluceda explains how.

Eluceda’s testing solution uses its E-Sens™ digital reader in combination with a specialised electrochemical sensor.

Any manufacturer using water in large quantities or managing water infrastructure such as pipes will be familiar with the issues posed by biofilms, especially within the paper and pulp sector. Microorganisms (such as bacteria) have a tendency to cluster and bond together, forming biofilms.1 In water, these collections of biological material will float to the surface and begin to proliferate.

If not dealt with, these biofilms can slough off and accumulate on vital rolling and cutting machinery further down the production line causing dark coloured specks, or for the paper to stick to the rollers and holes and tears (resulting in significant re-work) or causing damage to the equipment itself. Contamination of paper by bacteria is also possible which can significantly affect the quality of the paper or board.

This known issue is inherent to managing water systems and the standard solution for the paper and pulp sector is to introduce hydrogen peroxide which has a dual role of bleaching the paper and to breaking down these biofilms.

But how do manufacturers know how much peroxide to use?

Precise measurement is one solution, but for many manufacturers existing testing methods are too impractical to allow for a more resource efficient approach, either taking too long to achieve a result (and thus slowing down production) or being an analogue process (i.e., using dipsticks with human eye confirmation) and hence prone to errors.

Because of this, many paper mills will use more hydrogen peroxide than is strictly necessary to be absolutely sure that biofilms have been removed. However, rising raw material costs and increasing pressure for businesses to be more water efficient demonstrates that a more measured approach is needed by the sector.

Detection technology business Eluceda has developed a testing solution for the paper and pulp sector that overcomes previous testing limitations, giving manufacturers access to accurate, digital data on both biofilm and hydrogen peroxide levels in an easy to use ‘dip and read’ test format.

Eluceda’s testing solution uses its E-Sens™ digital reader in combination with a specialised electrochemical sensor. When submerged in a relevant water sample the electrode provides an accurate, quantitative reading within minutes, even in the presence of pulp. This means that water samples no longer need to be sent to a laboratory or have lengthy waits for results, the detector is the ‘lab’ in this sense, providing detailed, accurate data on site and in real-time.

Precise knowledge of biofilm contamination levels allows production management to know how much peroxide is needed, enabling for much more efficient use of materials. The same detector can then also give an accurate reading of H2O2 concentrations to ensure that correct levels are maintained without lengthy (and costly!) pauses in production.

The obvious benefit to taking a much more measured approach to peroxide is the potential raw material savings it allows, but there are other key benefits to be taken advantage of as well. We live in an age where data is an incredibly valuable resource, and the digitalisation of the process, gathering data gained from testing solutions such as this is no exception.

Eluceda’s solution provides manufacturers with a valuable data set that can be stored, analysed and shared with relevant stakeholders – even remotely. This is of benefit to paperboard manufacturers who supply to food packaging businesses who have strict compliance regulations with regards to contamination. The technology gives the ability to share real-time data with customers of initial biofilm levels, amount of peroxide applied and resulting biofilm levels with customers, helping to reassure all partners throughout the supply chain – without significant monetary or time costs.

In summary, today’s detection technologies are not only enabling precision manufacturing and more effective use of valuable raw materials in production, they can also empower paper mills with access to valuable data. This digitalisation of the testing process helps deliver even greater benefits, using technology to retain and share information, providing the reassurance required in today’s manufacturing environments.

1 Terlizzi, A. and Faimali, M., “Fouling on artificial substrata”. In: S. Dürr & J.C. Thomason (eds) Biofouling, Wiley-Blackwell, Oxford, pp. 170-184 (2010).

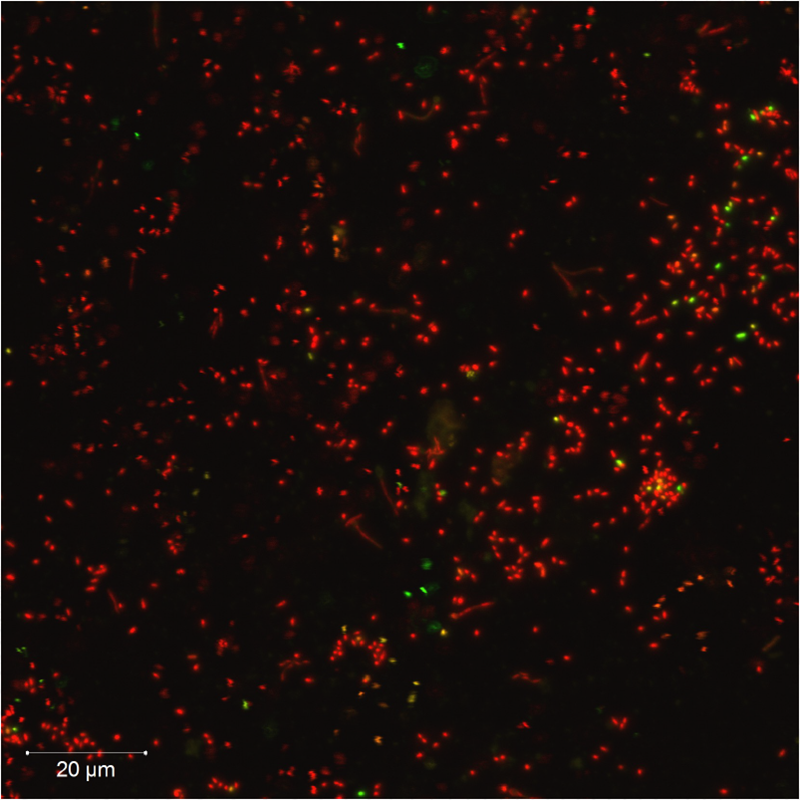

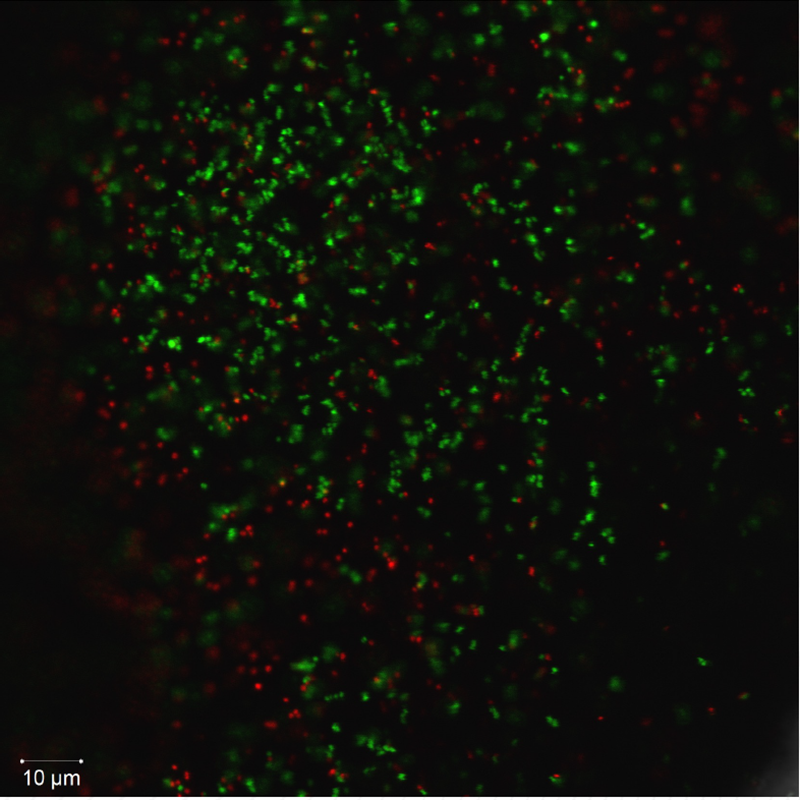

Biofilms present in a water sample; live bacteria are green “dots”, red are dying, becoming black when dead.

Author: Dr Ian Eastwood, Chief Technology Officer at Eluceda.

Editor: sbr

Images: Eluceda