P3 3-4/2022 en

What Does it Mean ...

Trapping vs Trapping

Education Gap

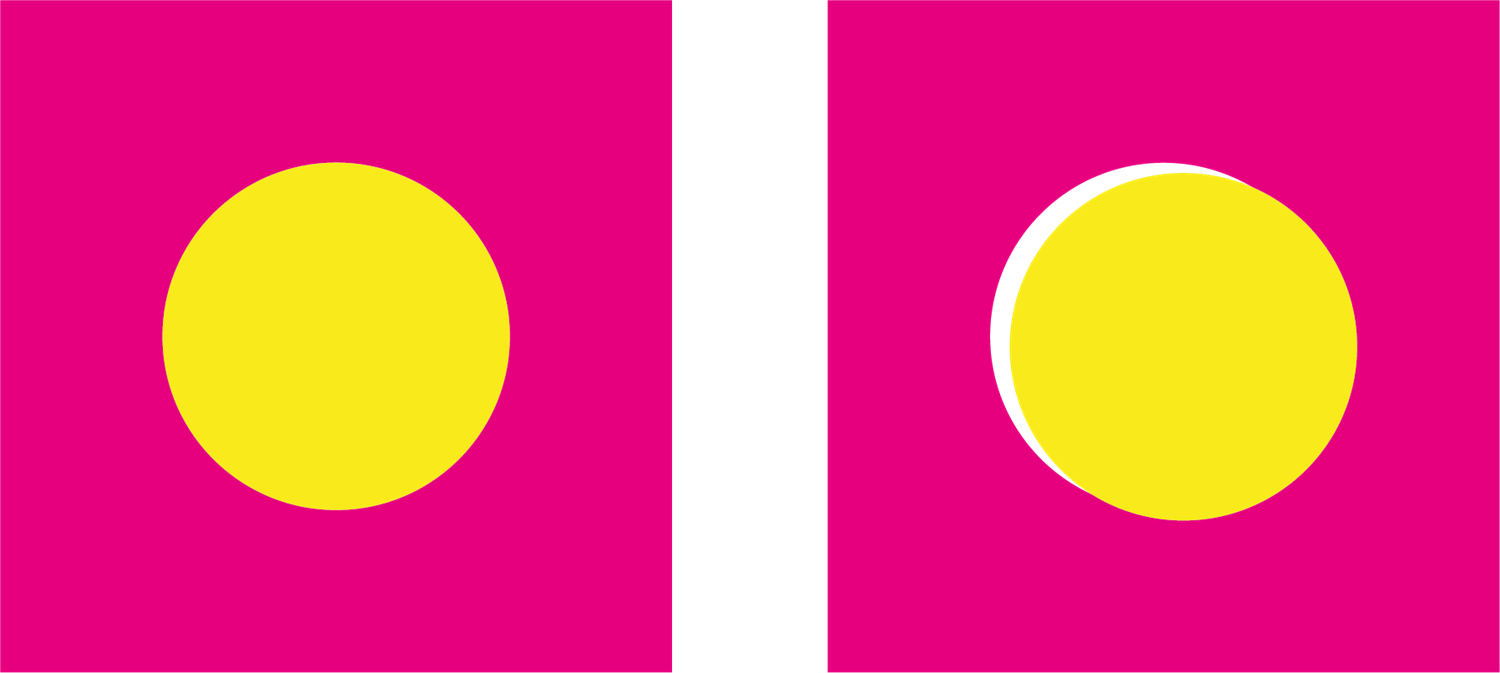

Fig. 1: left: correct position of magenta and yellow, right: white gaps due to incorrect position of the circle.

It can happen that a technical term is used more than once. This is the case with “trapping”, for example. Extensions such as "Contour Trapping" and "Ink Trapping" are used to differentiate between them. Ronald Weidel from the Gutenberg School in Leipzig explains the term. Or does it have to be: the terms?

Fig. 1: left: correct position of magenta and yellow, right: white gaps due to incorrect position of the circle.

In prepress, the term trapping or contour trapping is used synonymously for the German technical terms overfilling and underfilling. This is a reproduction process with the aim of optimizing print data for the corresponding printing process. In multi-color printing, position fluctuations between the individual printing units are inevitable. There are many possible causes for this - faulty print processing, stretching of the material due to ink absorption, etc. These register differences become particularly clear to the viewer when they lead to unprinted defects, so-called white gaps. Figure 1 shows the desired position of the colors on the left. Gaps occur on the right side as a result of fluctuations.

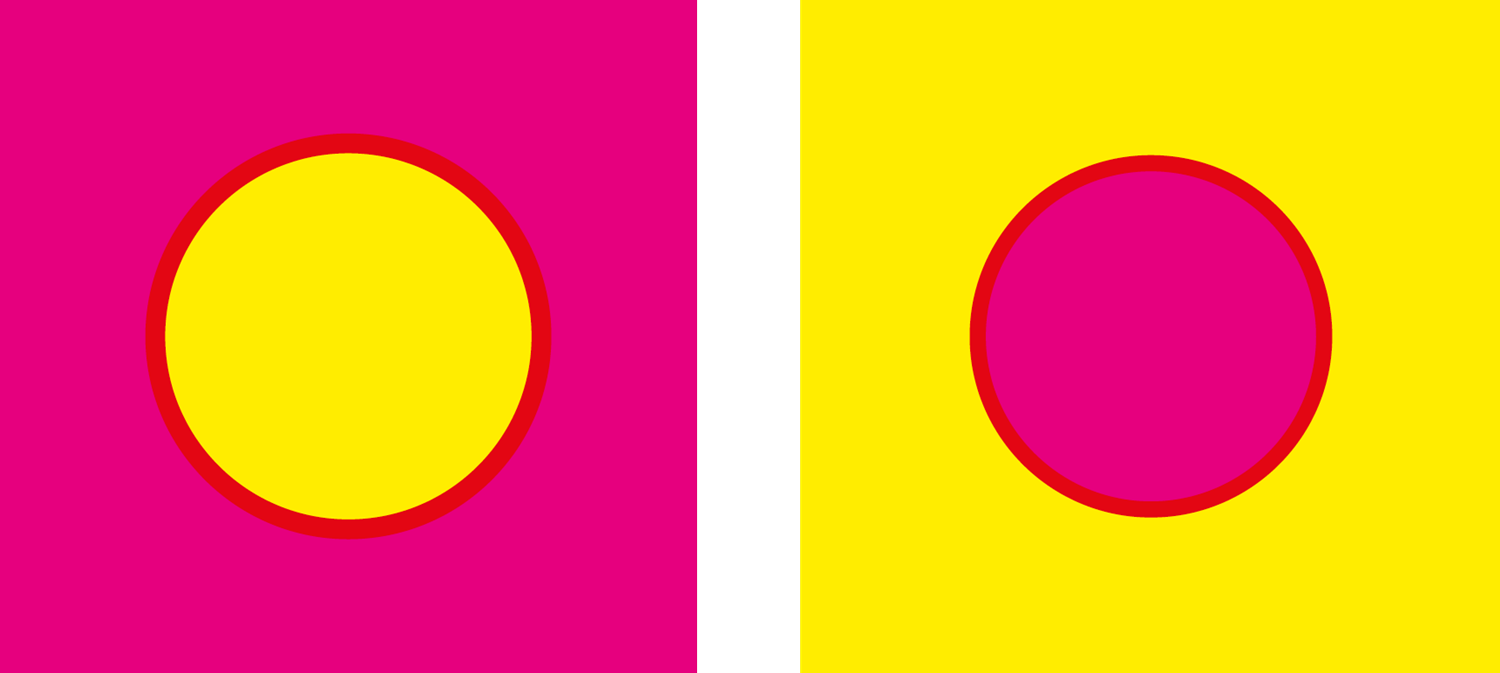

Trapping helps here by expanding adjacent objects in the contour. An overlapping area is created that conceals tolerances in the print and reduces gaps. The basic rule of trapping is that the lighter color is spread or choked into the darker color. Figure 2 shows trapping on the left. The yellow circle is given an expanded outline. The right side shows an underfill. The yellow background expands under the magenta circle. The degree of overfilling or underfilling depends on the printing process. For example, flexographic printing requires a larger contour than offset printing due to larger tolerances in the printing process.

In the printing process, on the other hand, the term trapping describes the ink trapping behavior. In the multicolored printing process, color layers are printed next to and on top of each other. While the first color is printed on a free substrate surface, all other colors are also partially printed on preceding colors. The conditions in the first printing unit thus differ significantly from the subsequent printing units. In wet-on-wet printing in particular, the changed surface properties affect ink transfer. A damp ink film noticeably reduces the initial adhesion on the substrate, and the subsequent amounts of ink decrease. This effect can be clearly demonstrated by swapping the color sequence. In this context, trapping is often only spoken of when the disturbed ink trapping leads to visible dropouts in the printed image or to color changes.

The case study in Figure 3 is intended to illustrate this. The print job consists of two colors (orange background and blue font). It is printed on corrugated cardboard using flexographic printing with water-based ink. The planned color sequence is orange and blue. The font is set to overprint and is not left blank in the background. The left half of the figure shows the result after the proof. The overprinting blue partially breaks up and the background shines through in orange. The right half shows the print result after the color order has been swapped. In addition to the change in the color mixture (the blue writing becomes greenish), the overprinting color also breaks up again. However, the contrast is significantly lower. In the present case, the color sequence was swapped back again in order to obtain the correct color impression. Due to the low ink coverage on the 6-color printing machine, the first and last printing units were occupied, thus lengthening the drying path for the first color. The trapping could be largely reduced by this measure.

Fig. 2: left: overfilling by expanding the circle contour, right: underfilling by expanding the left-out yellow area.

Author and Dipl.-Ing. Printing Technology (FH) Ronald Weidel has been working at the Gutenberg School in Leipzig as a teacher for printing technology since 2008.

Author: Ronald Weidel

Editor: sbr

Images: Ronald Weidel