P3 3-4/2021 en

What Does it Mean?

100% Inline Inspection

Education Gap

When describing professional printing processes (not only) in packaging printing, there is no getting around the 100% inspection. Lucia Dauer, Product Manager Print Inspection, ISRA VISION, explains the term.

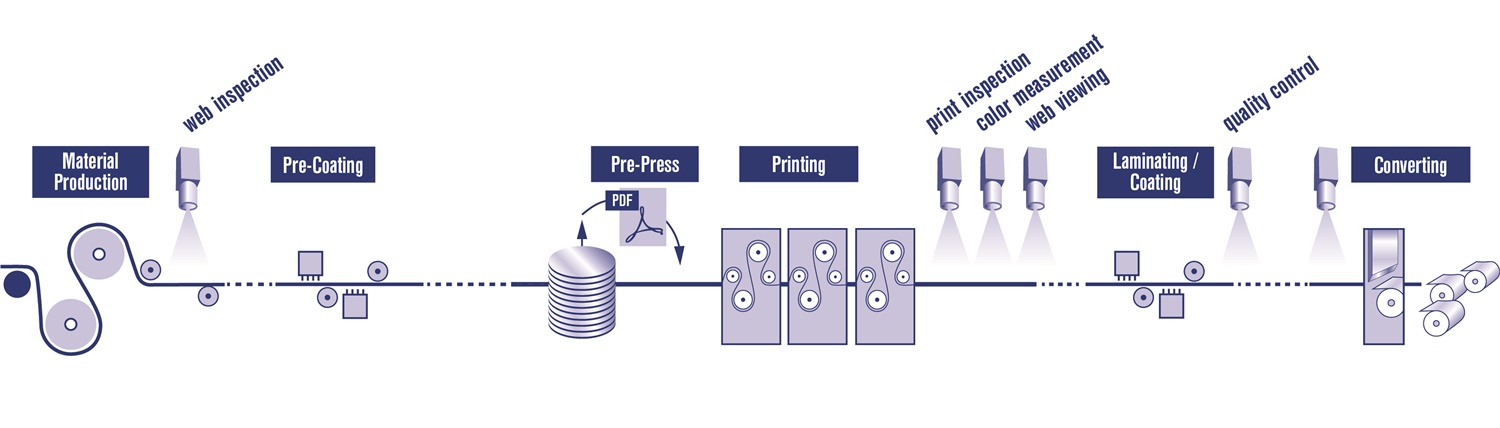

100% Inspection: Process overview.

High-quality packaging means that printing companies must deliver goods that are absolutely free of defects. This applies to flexible packaging as well as to printed corrugated cardboard or metal packaging. The monitoring of the printing process and the fastest possible reaction to printing errors are crucial. For this purpose, inline inspection systems, e.g. from ISRA VISION, are used for one hundred percent quality control and an efficient workflow.

The inspection systems with high-quality camera and lighting technology are installed on the printing machines. They start checking as soon as the printing process is initiated - by comparing the print template. They also support color control during the make-ready process so that print production can start as quickly as possible with the right settings. During the printing process, they identify defects that occur once or repeatedly, such as streaks, spatter, register errors or the like, in real time and, through appropriate alarm signals, ensure that the operator can immediately take appropriate corrective measures. This prevents waste or costly reprints. Web monitoring systems give the operator an image section as a static image in order to enable additional visual control at full production speed.

Systems attached to conversion machines monitor the quality in the further processing process, e.g. lamination or roll assembly with cutting and reeling processes.