P3 5-6/2021 en

29 Mio. kWh Electricity

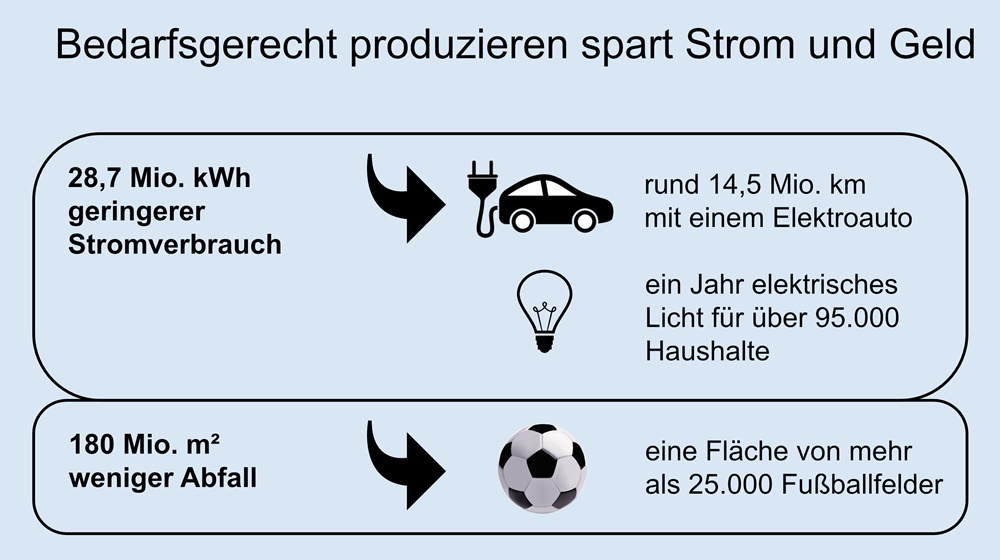

Producing as Needed Saves Electricity and Money

Standards

New studies by the independent consultancy Smithers show how European companies save significant amounts of electricity, CO2 and waste thanks to needs-based labeling with inkjet printers. In addition, the production processes are becoming significantly more efficient and sustainable.

If every European company switched to needs-based labeling with inkjet printers, almost 29 million kWh less electricity would be used every year. This corresponds to the amount of electricity required to illuminate 95,960 houses in one year and a reduction of 6.7 million tons of CO2. With inkjet printing tailored to one's needs, up to 180 million square meters of waste of unusable label material could also be avoided. That corresponds to the area of more than 25,000 soccer fields. In addition, the reduction of unnecessarily printed label materials would reduce the consumption of more than 600 tons of ink.

Smithers conducted a survey to compare the sustainability of different printing processes and assess how they help manufacturers achieve their sustainability goals. To this end, the institute analyzed companies that use a number of commercial thermal transfer and inkjet printing processes internally. From the consumption values of the productions, it calculated a sustainability rating in various key categories such as electricity, waste, consumables, storage and transport.

It concluded that using inkjet technology to print labels in-house has great commercial and operational benefits such as lower power consumption and less waste, making it environmentally friendly. This supports companies in achieving the following UN sustainability goals:

SDG 7 Affordable and Clean Energy: Inkjet technology is a far less energy-intensive process than many traditional processes and requires only a fraction of the electricity.

SDG 8 Decent Work and Economic Growth: Inkjet printing is cost effective and improves margins for label printer users.

SDG 9 Industry, Innovation and Infrastructure: Innovative inkjet technology reduces waste of unusable label materials due to overproduction.

SDG 12 Sustainable Consumption and Production: Inkjet printing generates significantly less waste than thermal transfer printing.

Jörg von Ahlen, Head of Marketing at Epson Deutschland GmbH, comments: “Labels are a crucial means of ensuring the success of brands in a large number of industries. Choosing the right label printing process is important when it comes to commercial benefits in terms of go-to-market, flexibility, and quality. In the meantime, more and more companies are switching to needs-based color label printing with inkjet technology, as this makes an important contribution to achieving a company's sustainability goals and improving efficiency. Choosing inkjet printing tailored to your needs lowers overall power consumption and the amount of waste generated. It reduces rejects and overproduction and minimizes the cost of consumables. The optimization of the supply chain as well as a steadily better recycling of ink cartridges further improve the advantages of ink printing in terms of sustainability.”