P3 7-8/2020 en

PapierLicht

A Lampshade as a Demonstrator for Bodies Made of Structure Winded Paper Yarn

Innovation

The Department of Paper Manufacture and Mechanical Process Engineering (PMV) at TU Darmstadt and the German Institute for Textile and Fiber Research Denkendorf (DITF), together with the industrial partners GarnTec GmbH, a manufacturer of paper yarns, and quintessence design, an industrial design agency, have worked out basic information for processing paper yarns to self-supporting, three-dimensional structural bodies. In the paper light project, sponsored by the Deutsche Bundesstiftung Umwelt (DBU) (grant number 35166/01), new applications for paper yarn as a material for the production of sustainable consumer goods were demonstrated using the example of light structures.

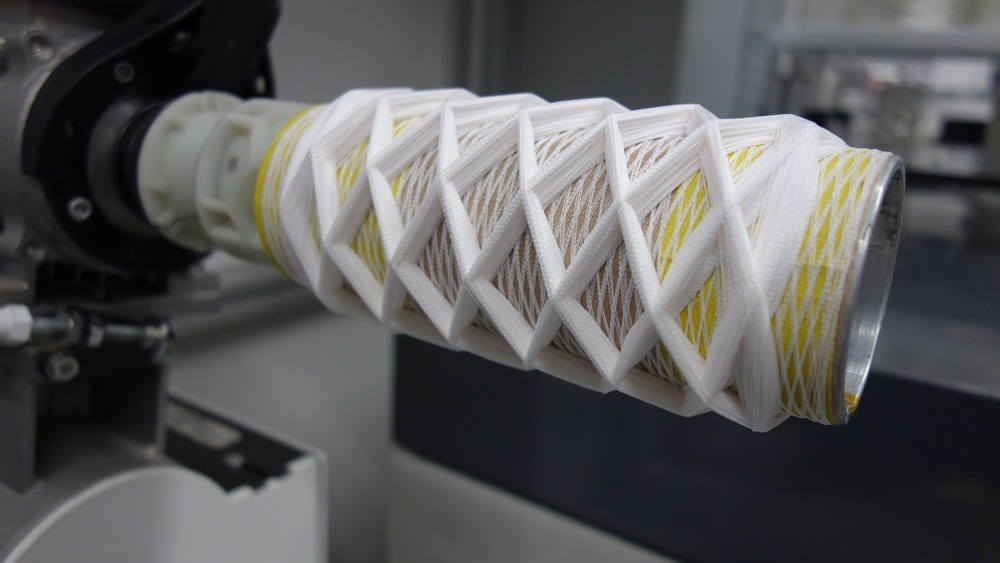

Figure 1: Structure bobbin on the winding machine.

Using structure winding technology, three-dimensional bodies can be produced from paper yarns. For this purpose, the yarn is placed in a controlled manner on a mandrel that defines the shape during the winding process. Different structures can be set up by varying the speed ratios.

The structures produced in this way are then consolidated into self-supporting, stable components. For this purpose, adhesives and processes adapted to them were used, which do not show any negative process effects in a subsequent recycling process.

The design ideas developed were embedded in current living trends with the aim of achieving a high level of user acceptance. The implemented structures take up elements from the Scandinavian living style and show parallels to the well-known Viennese wickerwork, which is more and more often used in many pieces of furniture and furnishings. The design process was supported by a simplified simulation of the lighting effect in the room. The lighting parameters were determined from the samples produced and are therefore available for further design tasks.

The complete lights just consist of - with the exception of the electrical components - typical paper components. At the same time, the paper yarns made allow to create structures with exciting looks and haptics, which at the same time show good mechanical and lighting properties.

Wire was left out for building the supporting structure. Together with the recycling potential the results represent the basis for the desired transfer of the information acquired to other application ideas and products.

Further information can be found on the project homepage: www.papierkonstruktion.de.

Authors: Kathrin Haigis (DITF), Robert Götzinger (PMV), Viola Finckh (DITF), Christoph Riethmüller (DITF), Karl Schairer (quintessence design), Nathalie Heeb (quintessence design), Gerd Martin (GarnTec GmbH), Prof. Samuel Schabel (PMV), Prof. Götz T. Gresser (DITF).

Editor: sbr

Photos: DITF