NEWS powered by

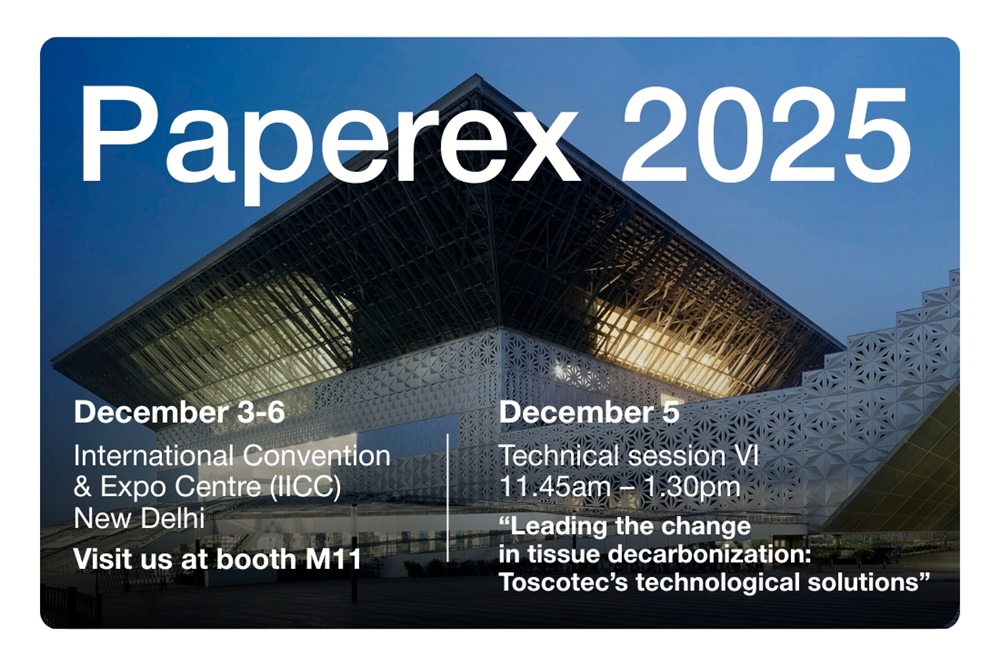

Toscotec: Proven electric energy solutions in New Delhi

Toscotec is set to showcase sustainable tissue solutions at Paperex 2025, the internationally renowned series of exhibitions and conferences focusing on paper, pulp, and allied industries. From December 3-6, Toscotec will be present at International Convention & Expo Centre (IICC) in New Delhi, India, with a dedicated booth M11 – together with Voith and BTG. Visitors can explore the latest technologies designed to accelerate decarbonization and efficiency in tissue production.

Vitrapack accelerates productivity and sustainability with new Bobst Expert CI flexo press

To keep pace with rising demand and customer expectations, Vitrapack has strengthened its capabilities with the addition of a Bobst Expert CI flexo press. The investment not only boosts capacity, but also enhances flexibility and sustainability, enabling the Belgian packaging producer to handle even shorter lead times, adapt to a wider range of job requirements, and maintain consistent print quality, while keeping waste levels low.

Södra wins Växjö municipality’s timber construction award 2025

Södra has been named the winner of Växjö Municipality’s Timber Construction Award 2025 for its long-term and sustainable approach to timber construction. The award recognises those driving progress in sustainable building and inspiring continued innovation.

Södra tests carbon capture technology in Värö

In early 2026, a pilot project for carbon capture will be launched at the Värö industrial site. The initiative aims to build knowledge around the technology and explore new business opportunities using biogenic carbon dioxide as a raw material. The pilot is part of Södra’s long-term strategy to increase the value of every tree, strengthen competitiveness and contribute to more profitable forest estates. By testing new technology to capture biogenic carbon dioxide in an industrial setting, Södra seeks to explore how this resource can be refined and used in new applications without increasing forest harvesting.

Toyo Ink India to boost liquid ink production capacity by 1.5 times

Toyo Ink India Pvt. Ltd., a member of Japan’s artience Group, has announced plans to expand liquid ink production at its Gujarat Plant, in western India, to meet burgeoning demand from the country’s packaging market. The new facility, which is scheduled to be operational in 2028, is expected to boost the company’s total production capacity by approximately one-and-a-half times.

Valmet’s new waste-to-energy boiler to help Cheng Loong Corporation in Taiwan

Valmet will deliver a CFB boiler, flue gas treatment and automation system for Cheng Loong Corporation’s (CLC) Houli paper mill in Taiwan. The boiler will use various waste and biomass streams as fuel to produce electricity and heat for the mill. The new boiler is a significant investment in decarbonization of the mill as the new boiler will enable the reduction of coal usage and replaces an older less efficient waste boiler. CLC has estimated that this new boiler will reduce mill’s annual CO2 emissions by 48,000 tonnes. The order is included in Valmet’s orders received of the fourth quarter of 2025. The value of the order will not be disclosed.

Color-Logic adds Konica Minolta as certified reseller

Color-Logic is pleased to announce that Konica Minolta Business Solutions U.S.A., Inc. (Konica Minolta) is now a certified reseller of Color-Logic Solutions. This strategic alliance enables Konica Minolta to offer its clients industry-leading Color-Logic solutions across a range of digital presses, including the AccurioPress C14010S/C12010S, equipped either with the AccurioImage IC-614 Controller or the Fiery !C-322/IC-323, and the AccurioLabel 400 digital label Press. The compatibility of these presses with Color-Logic opens new avenues for high-value eye-catching print applications.

Mondi launches extended corrugated and solid board portfolio for the food packaging industry

Mondi is strengthening its position as a trusted partner for the food industry with the launch of an extended food packaging portfolio. The portfolio now includes solid board solutions and digital printing capabilities following the acquisition of Schumacher Packaging, enhancing Mondi’s ability to serve customers across Europe.

UPM Communication Papers launches climate action roadmap

UPM Communication Papers is launching a new climate action roadmap, marking a significant milestone in accelerating its climate actions. The initiative reinforces its long-standing commitment to sustainability and further supports its customers in achieving their climate targets. The roadmap builds on UPM Communication Papers’ existing climate goals and commitments setting out concrete actions to further reduce carbon emissions across the paper value chain.

Swiss media house invests in digital printing solutions from Heidelberg

When an agency discovers digital printing, exciting times lie ahead! The Swiss media house rubmedia, which has 35 employees, focuses on creative communication solutions for service providers, associations, and the worlds of industry and politics. With this in mind, the company has commissioned a compact, highly automated digital printing line at its new Köniz site, near Bern. The new production operation centers around the Jetfire 50 and the Versafire LV from Heidelberger Druckmaschinen AG (Heidelberg), complemented by an in-house third-party postpress system.

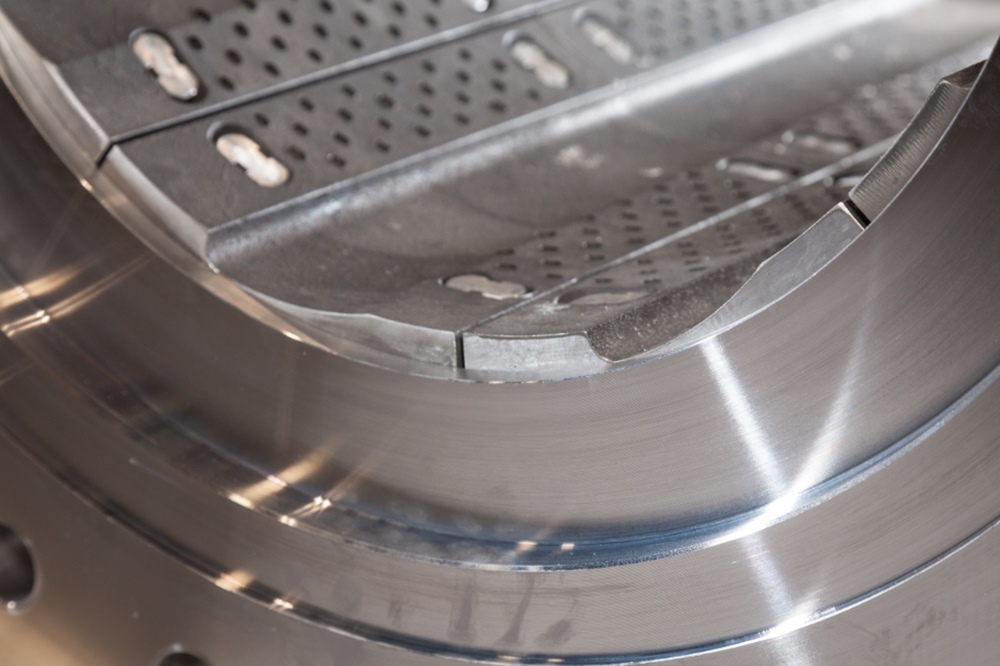

Metro Decorative places repeat order for advanced Andritz pressurized refining system

Metro Decorative Pvt. Ltd., India has placed an order with international technology group Andritz for the supply of a second pressurized refining system to its medium-density fiberboard (MDF) production facility in Kashipur, Uttarakhand. The order value will not be disclosed. It is included in Andritz’s order intake for the third quarter of 2025.

Cortec® expands sustainable packaging options with new EcoBio™ barrier paper

Cortec’s barrier paper portfolio just got more sustainable! Industries looking for environmentally responsible options in the area of barrier packaging should take a closer look at the new EcoBio™ Barrier Paper, a premium recyclable, repulpable, biodegradable barrier paper designed with the “circular economy” in mind.