NEWS powered by

Fiery XF 9 unlocks new ways to produce high-value large format print

Fiery, LLC announces the launch of XF 9, the latest release of Fiery’s high-performance software RIP, color management, and workflow solution designed to streamline all aspects of large format print production. Winner of the 2025 Pinnacle Award for best large format RIP software, Fiery XF 9 adds cutting-edge capabilities that unlock new levels of value out of your large format print operations.

Sara Ghione joins Omya Performance Polymer Distribution as President for Rubber Polymers and Additives

Omya Performance Polymer Distribution has appointed Sara Ghione as President for Rubber Polymers and Additives, effective January 1st. Based in Oftringen, Switzerland, and reporting to CEO Carsten Harms, Sara has over 20 years’ experience in the chemical distribution industry, most recently as Business Director for Polymers and Rubber EMEA for Brenntag.

Heidelberg strengthens financing structure

Heidelberger Druckmaschinen AG (Heidelberg) has reorganized its Group financing to further optimize its financing structure. At the start of the year, the syndicated credit line arranged in 2023 was replaced by a new consortium loan facility and extended up to 2030 ahead of its maturity date. The facility amount has been increased to € 436 million and has been implemented with a slightly different group of banks.

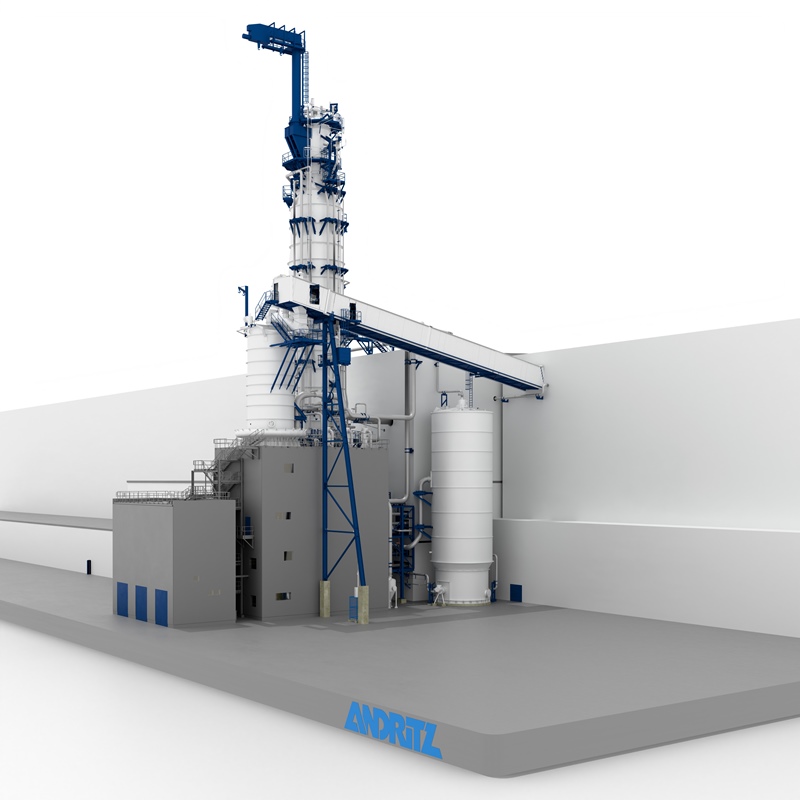

MM Group orders continuous cooking plant from Andritz

International technology group Andritz has received an order to supply a new cooking plant to MM Group’s integrated pulp and paper mill in Kwidzyn, Poland, supporting the mill’s major sustainability and energy-efficiency upgrade program. Andritz will replace the mill’s batch digester cooking plant with a LoSolids continuous cooking plant designed to switch between softwood and hardwood pulp production. This investment will significantly reduce energy consumption and CO2 emissions at the MM Kwidzyn mill.

Change in SCA's Group Management

Anders Edholm, Senior Vice President Sustainability and Communications, has decided to leave SCA during 2026 to take up a position with another company. Anders Edholm will remain in his role as Senior Vice President Sustainability and Communications until 31 July 2026. The process to recruit a new Senior Vice President Sustainability and Communications will commence immediately.

Mutoh EMEA introduces XpertJet 1641SR PRO II 64" Eco solvent printer

Mutoh Europe nv, EMEA business unit of Mutoh Industries Co. Ltd., Japan, proudly announces the launch of its new 64"/1625mm Eco-Solvent printer XpertJet 1641SR Pro II. The new model combines Mutoh’s latest AccuFine HD Pro print head with the innovative i-Screen EX System and uses MS51 inks, delivering top-class productivity of up to 17.6 m²/h and exceptional image quality.

Kanematsu launches new large format card printer

Kanematsu GmbH has announced that it will become the lead distributor for the Canon CX-G6400. The printer will be available across Europe, the Middle East, and Africa (EMEA), offering a unique solution for event badge printing.

IBS Group successfully commissions starch preparation plant at Mondi Štĕtí

PGA Anlagenbau, a member of the IBS Paper Performance Group, is celebrating the successful commissioning of a complete starch plant for mass starch preparation at Mondi Štetí, Czech Republic. The plant is destined for the state-of-the-art new paper machine, which went into operation in December 2024. An essential component of the plant is the patented starch cooker PGA starchPerformer.

Yarn spinning partner Tearfil continues to support Spinnova’s fibre and technology

Spinnova Plc has signed non-binding Letter of Intent (LOI) with Portuguese yarn spinning company, Tearfil Textile Yarns to secure access to Spinnova® fibre volumes. The LOI outlines an important step in Spinnova’s ambitions to create an ecosystem (consortium) to enable the availability of textile materials with sustainable Spinnova® fibre in the textile materials market.

Kesla sells the product rights of its previously discontinued wood chipper product group

Kesla announced in June 2025 that it had decided to discontinue its wood chipper product group as part of the company's strategic review. At the same time, the company initiated a sales process for the product rights related to wood chipper products. On 17 December 2025, Kesla signed an agreement to sell all product rights related to wood chipper products to the Lithuanian mechanical engineering company UAB Ukmergès Staklès.

Andritz starts up sludge drying plant at Eldorado Brasil Celulose

International technology group Andritz, which supplied the technology and developed the new biological sludge drying plant for Eldorado Brasil Celulose’s pulp mill in Três Lagoas, Brazil, celebrated the plant’s successful start of operations. This project represents another step forward in Eldorado’s strategies to transform waste into energy and enhance the environmental efficiency of its operations.

Miraclon strengthens global service network

Miraclon today announced the appointment of Rajagurulingam (Raja) Ramalingam as Service Manager for the Asia Pacific Region. Based in Singapore, Raja will lead the company’s regional service organization, driving excellence in customer service and technical support, field performance, and operational execution across the region.