NEWS powered by

Labelexpo

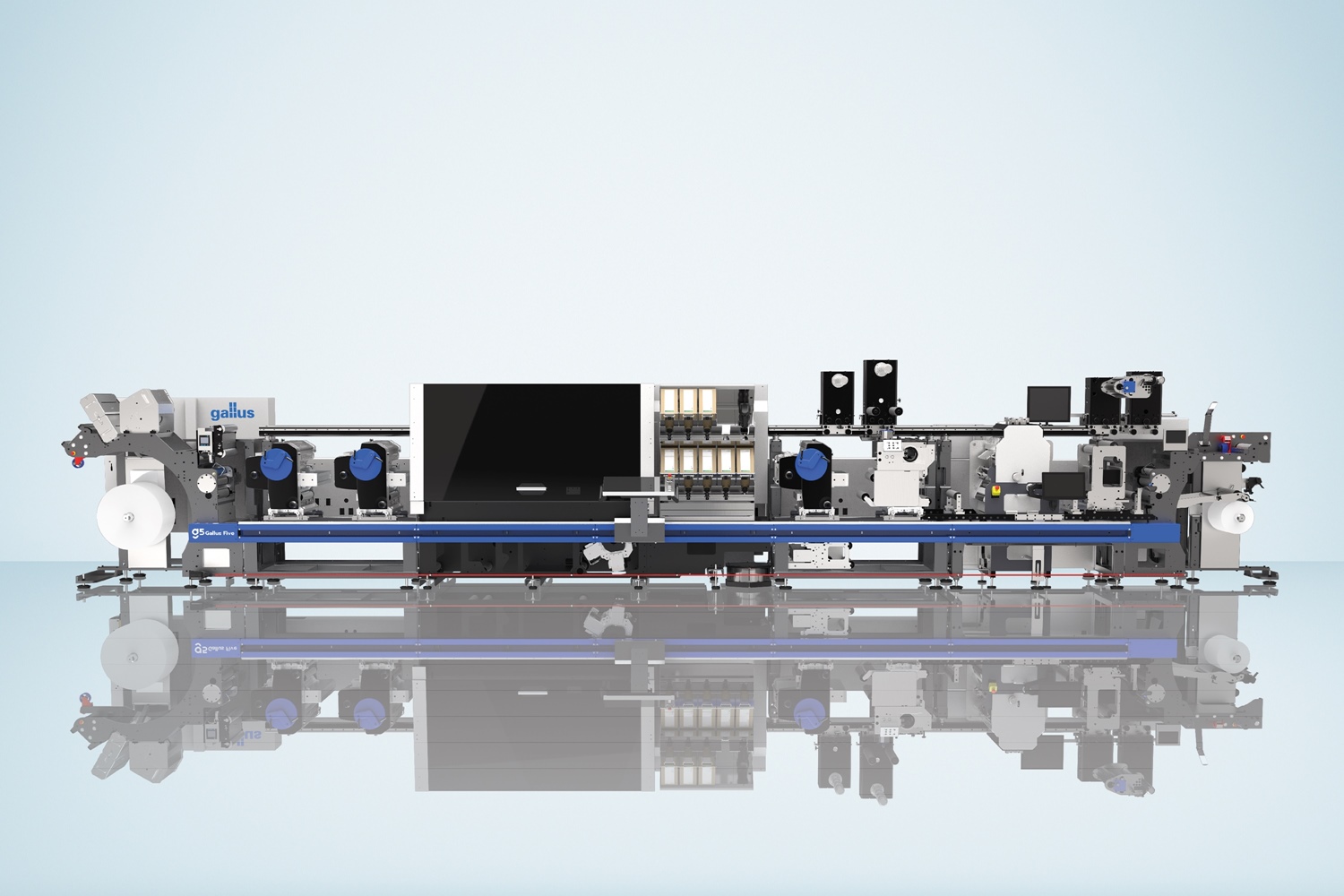

Gallus and Heidelberg unveil new digital and hybrid solutions to meet rising demand across the label market

Gallus, a subsidiary of Heidelberger Druckmaschinen AG (Heidelberg), today announces the launch of two new presses, one all-digital and one hybrid, at Labelexpo Europe 2025. These additions to its System to Compose portfolio have been strategically developed together by Heidelberg and Gallus to address the pressing and evolving needs of label producers to deliver greater speed, flexibility, and high-quality output.