P3 3-4/2024 en

DM-Maxliner 2D

Substrate Limits are so Last Season

Finishing Technology

With the global market launch of the DM-Maxliner 2D in Düsseldorf, Kurz is expanding the landscape of digital embellishment.

The technology of the DM-Maxliner 2D, developed by Leonhard Kurz and Steinemann DPE, represents a step forward in digital embellishment. This approach enables high-precision metallization of a wide range of substrates, helping to maximize production efficiency and bring print production one step closer to industrialization.

With the global market launch of the DM-Maxliner 2D in Düsseldorf, Kurz is expanding the landscape of digital embellishment.

Globally active in thin-film technology and digital finishing systems, Kurz offers consumables and machines tailored to the system. Customers benefit from decades of technical expertise and a wide portfolio of digital embellishment equipment with three different product platforms and eight different products for sheet and roll printing applications. At the world’s largest trade fair for the print media industry, Drupa, the company will be presenting its expanded digital embellishment solutions portfolio under the motto ‘Re:think what’s possible.’ This motto underscores Kurz’s commitment to driving innovation and technological progress in the industry.

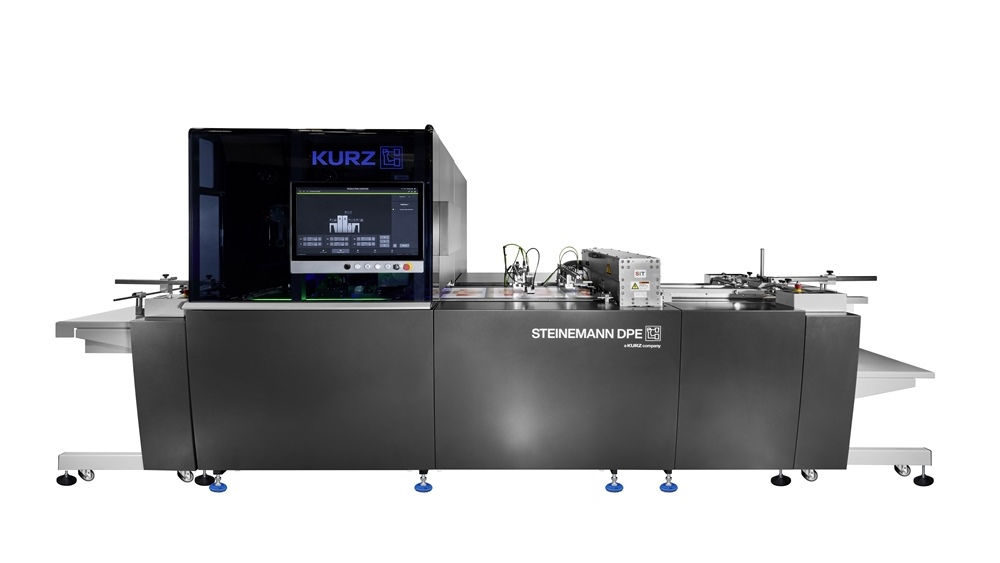

With the global market launch of the DM-Maxliner 2D in Düsseldorf, Kurz is expanding the landscape of digital embellishment. The machine, developed by Kurz and its subsidiary Steinemann DPE, offers a new approach to digital sheet-fed metallization and combines cutting-edge technology with versatility.

The DM-Maxliner 2D enables digital metallization for a wide range of substrates, including uncoated papers with an open structure, at full operating speed in a single pass. What’s more, The DM-Maxliner 2D is characterized by industry-leading production speed, efficiency, and high quality for optimum embellishment results. The core innovation, Kurz’s patented inkjet-on-transfer technology, enables precision and repeatability. Ordinary print jobs are transformed into extraordinary, market-ready products - at high production speeds.

“The DM-Maxliner 2D is the result of years of research and development, and we are delighted to present this innovation for digital sheet-fed printing to a professional audience,” says Michael Aumann, Global Director Digital Embellishment Solutions at Leonhard Kurz. “Our customers will benefit from this technology as they are now able to make the most of the possibilities of a fully digital workflow including embellishment. The combination of a fully digital workflow and the ability to process multiple substrates will change the industry.”

Innovation with patented inkjet-on-transfer technology

Thanks to its patented inkjet-on-transfer technology, the DM-Maxliner 2D stands for consistently high embellishment results on a wide range of substrates. Even with challenging structures such as uncoated papers - the DM-Maxliner 2D can handle a wide range of applications. The desired design is printed on the backside of the transfer material, which ensures consistent conditions for the print process. This makes brilliant large surfaces and delicate structures possible - on almost any substrate.

Even demanding requirements such as higher capacities and high-quality production at the same time are no problem. Each sheet can be individually designed according to customer requirements - thanks to variable data. Simple and repeatable work steps in the printing process enable users to quickly build up specialist knowledge and work effectively and productively in a short time, thus optimizing costs.

Efficient and cost-optimized work

Fast order throughput times, no tool costs and short set-up times enable maximum production speed and optimum efficiency. The DM-Maxliner 2D is designed for a highly digitized operation and enables automatic job changes without stopping the machine. It automatically recognizes orders by reading a data matrix code. Immediate job changeover occurs at full operating speed, allowing the production of multiple jobs without setup or adjustment effort. This results in continuous, uninterrupted operation, reducing operator intervention, material handling, and inventory.

Robust, reliable, and durable. Designed for industrial production.

With over 50 years of experience in developing and building machines for the printing and packaging industry, Steinemann DPE has built a reputation for delivering machines that work reliably for years to come. The DM-Maxliner 2D is also characterized by the robust durability and quality customers expect from Steinemann DPE worldwide.

What’s more, the DM-Maxliner 2D is designed to reduce wear and tear on key machine components. This leads to longer operating times and service life. Complemented by reliable service and low maintenance as well as a practical design, it enables maximum operator efficiency - even in small spaces.

Highest process stability and ease of use

High process stability and easy handling are no contradiction. An intuitive touch HMI display allows for easy operation. The user-friendly and intuitive design enables the machine operator to quickly achieve productivity and success. The production system controls all machine parameters to ensure optimum process stability and efficiency. Substrate classes can be conveniently stored to apply the same parameters repeatedly and ensure a consistently high quality level. Fast and precise setup further increases the efficiency of the DM-Maxliner 2D.