NEWS powered by

Södra divests its shares in Sunpine

Södra has reached an agreement to divest its shares in Sunpine AB to VAROPreem. The transaction is pursued together with shareholders Sveaskog AB and Lawter B.V., a subsidiary of Harima Chemicals Inc., and is now undergoing the necessary approvals before it can be completed.

India rising – Heidelberg strengthens presence in growth market

Dr. David Schmedding, Chief Technology & Sales Officer at Heidelberger Druckmaschinen AG (Heidelberg), visited the key market of India on a trip lasting several days. His meetings with numerous customers and partners during this visit provided impressive proof of India’s strategic importance for Heidelberg – especially in the areas of packaging and printing.

Tailored additives for coatings, printing inks, and more

Hubergroup Chemicals is expanding its portfolio with a new brand of high-performance additives: ELARA. The launch marks a significant step in the company’s evolution from a supplier of printing ink raw materials to a comprehensive partner for the coatings, inks, and adhesives industries. ELARA will make its official debut at Paint India 2026 in Mumbai, as a clearly structured additive portfolio supporting formulators in facing today’s complex technical and regulatory challenges.

Valmet’s automation boosts energy production flexibility at Fortum in Finland

Valmet is to deliver energy balance and district heating accumulator optimization solutions to Fortum’s energy production plants and assets in Espoo, Finland. The new solutions will be integrated with Fortum’s existing Valmet Distributed Control System (DCS), leveraging advanced automation and predictive energy management. The mission-critical solutions enhance the company’s flexible and reliable participation in electricity reserve markets while improving the cost efficiency of district heat production.

Sappi Europe announces price increase for label papers

Following an extended period of downward pressure, label paper prices have reached unsustainable levels. In the face of continued cost increases, Sappi Europe, producer of Label papers, announces 8% to 10% price increases for the Parade range of label papers including, non-wet strength and wet strength Wet Glue Label papers and Self-Adhesive Face papers, effective 1 April 2026.

The Navigator Company increases gKraft prices by 5-10% in April

The Navigator Company has decided to increase prices across its gKraft paper range by 5% to 10% depending on market and segments. The increase will apply to the entire portfolio of bleached and unbleached kraft papers and will be effective for all shipments starting April 1, 2026.

German UV curing technology meets Swiss coating solutions

Hoenle’s Business Unit Curing will present its curing and drying systems at Gulf Print & Pack 2026 in Dubai. As a development and solution partner for the printing and packaging industry, the German UV Technology specialist Hoenle will showcase its latest innovative and smart curing systems alongside coating solutions expert Mondula from Switzerland.

Agfa provides update on payment of the receivable related to the sale of Offset Solutions division

On 16 January 2026, Agfa announced that it had received the final report of the independent expert regarding the outstanding receivable under the share purchase agreement for the sale of Agfa’s Offset Solutions division. Further to this report, the payment of the price adjustment amount of 14.7 million euro (in respect of the disputed part) and the payment of 5.2 million euro (in respect of the undisputed part), in total 19.9 million euro, became due to Agfa on 6 February 2026.

Toyo Ink India inaugurates new research centre in Bengaluru

Toyo Ink India Pvt. Ltd., a member of Japan’s artience Group, announced the inauguration of artience Technology and Innovation Centre – India (aTIC-India) at the Indian Institute of Science (IISc), Bengaluru. This marks the Group’s first Research Centre outside Japan and a significant milestone in strengthening India’s role in advanced research, manufacturing, and sustainable innovation. A ceremony to mark the occasion was held on 4 February 2026 on-site of the new centre at the IISc campus.

Metsä Group and Andritz start up demo plant for new lignin products

Metsä Group and Andritz have successfully started up a new demonstration plant for lignin refining at Metsä’s Äänekoski bioproduct mill in Finland, marking an important step in the shift toward circular and renewable material solutions. The plant will enable Metsä Group to add new lignin products to its offering, while Andritz brings its LigniOxTM lignin recovery technology to demonstration scale.The project also involves Dow, a leading material science company, that collaborates with Metsä Group and Andritz to develop bio-based plasticizers for concrete and gypsum applications with modified lignin from the demo plant.

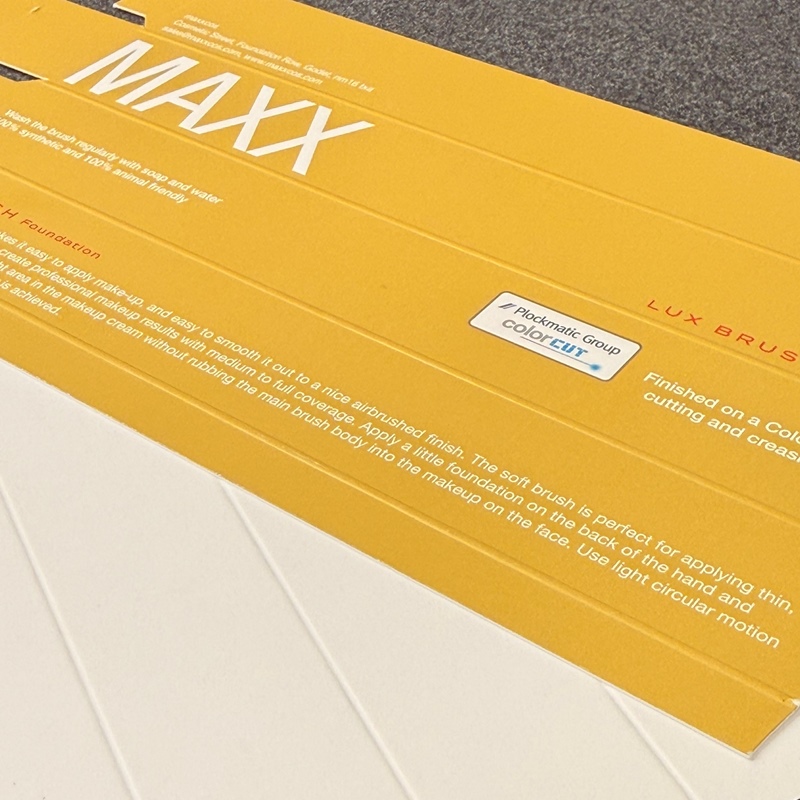

Plockmatic ColorCut SC7800 Pro-RS XL redefines cutting and creasing

The new design compact B2 digital sheet cutter and creaser is the latest addition to Plockmatic Group’s ColorCut SC7000 series. Its unique triple tool cutter/creaser incorporates a revolutionary, patent-pending, tangential creasing tool, with male (convex) and female (concave) elements to ensure superior double-sided creasing. With pressing and moulding tools that move above and below the sheet simultaneously, ‘formed’ creases are created similar to a metal rule platen machine.

Stora Enso releases climate resilience plan

Stora Enso has published a climate resilience plan outlining its approach to climate action, target attainment,?and business preparedness for future climate scenarios. The plan includes a forecast for emission reductions across all scopes by 2030. At the end of 2025, the Group’s Scope 1 and 2 CO2e emissions were 61% lower and the estimated Scope 3 emissions 38% lower than in the 2019 base year.?The target is to?achieve?a 50% reduction in all scopes by 2030.